1.) The majestic Yosemite Fall is located in the Sierra Nevada mountains within Yosemite National Park in Northeastern California. This iconic waterfall is a must-see attraction for visitors seeking the beauty of nature in its purest form. With its breathtaking views and awe-inspiring height, Yosemite Fall is a true gem of the park, showcasing the natural wonders of the Sierra Nevada region.

2.) The Cascades Diversion Dam, constructed in 1936, served as a hydroelectric facility along the Merced River until the mid-1980s. Following a devastating flood in 1997, the dam sustained significant damage, posing a threat to safety. Consequently, the decommissioning process commenced in 2003. Learn more at - www.nps.gov/media/video/view.htm?id=FA5B6C3F-BEFD-02EE-7BBC9FDE636B753C

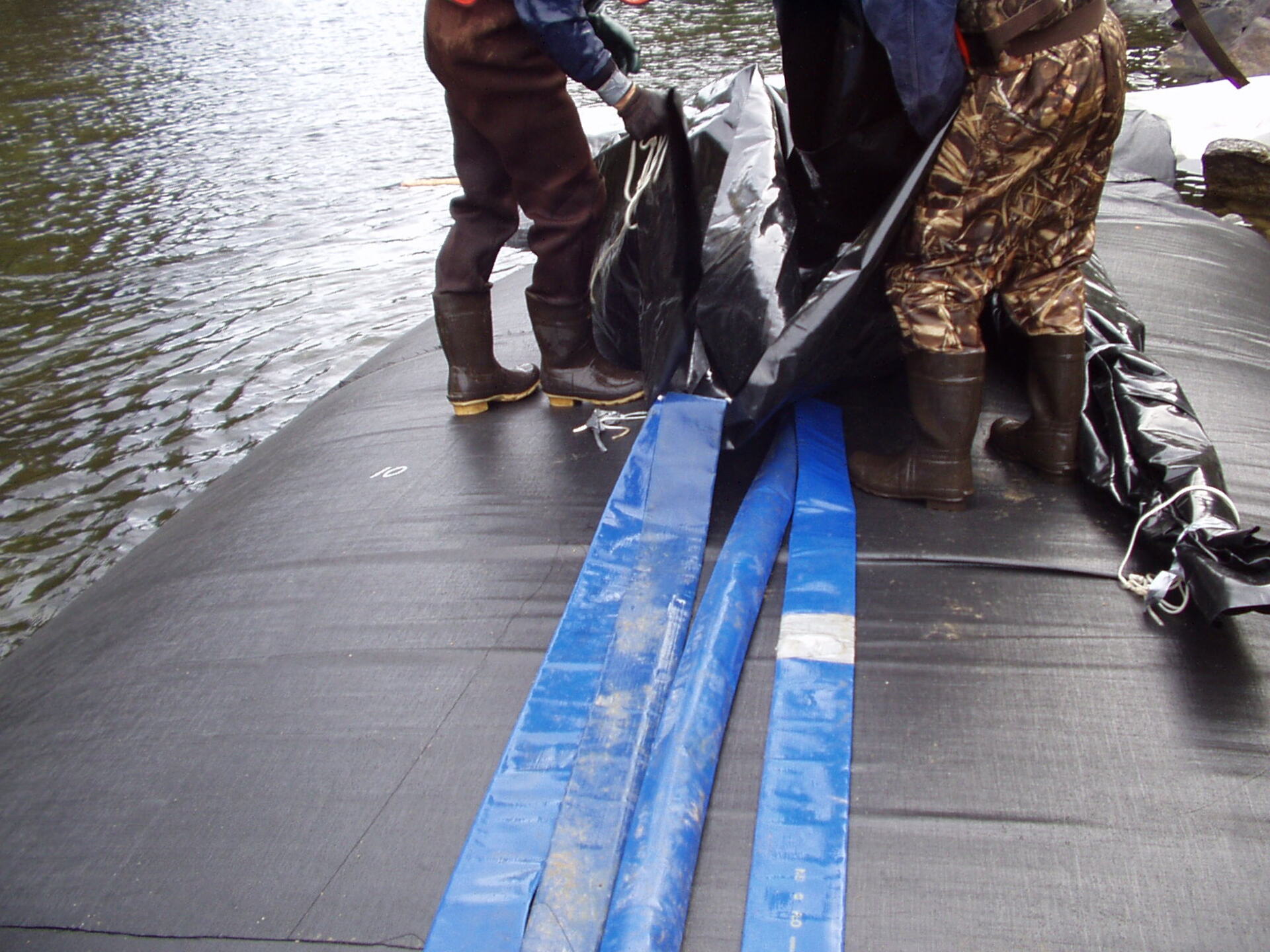

3.) In order to decommission the Cascades Diversion Dam, workers utilized a temporary cofferdam solution called AquaDam. The photo depicts workers holding the roll end of a single closed end (SCE) AquaDam® as it is being filled with water. Once the AquaDam® has accumulated several inches of head inside, above the surrounding water, workers will release a few feet of the roll and then secure it again, ensuring that the unrolled body of the dam remains above water.

4.) It is imperative that workers maintain the AquaDam's head above the water level in flowing water to prevent the flow from pushing the AquaDam® in an unintended direction.

5.) Once an AquaDam® has sufficient height above the water level of its surroundings, it can be utilized as a stable platform.

6.) Workers carefully transport the next AquaDam® to the closed end of the first one. AquaDams are delivered in a rolled-up form, resembling a carpet roll on a sturdy wooden beam. They are securely wrapped in a protective covering and come equipped with lifting ropes or straps for convenient transportation. While it may have been possible to float the AquaDam® to the end of the first one, the current of the river is flowing in the opposite direction.

7.) Workers cut the ropes used to secure the protective wrapping. This unit was a 5ft tall 11ft wide 110ft long (SCE) AquaDam® with a connection collar (W/C) and tapered fill-tubes (T.F.T.).

8.) Now that the protective wrapping has been removed we can see the material of the AquaDam.

9.) Workers are currently preparing the fill-tubes to connect this AquaDam® to the first one. The two AquaDams will be joined together using a connection collar, which will be attached to the closed end of one dam. The second dam will then be inserted inside and its fill-tubes will pass through the collar.

10.) Holes are strategically cut in the collar material at the closed end to allow for the fill-tubes of the next AquaDam® to pass through.

11.) The roll is floating in the water as workers start to feed the fill tubes and open end of the second SCE AquaDam® into the collar.

12.) As workers insert the fill-tubes through the designated holes, their colleagues assist by pulling on the tubes to facilitate the process. The open end of the second AquaDam® will be expanded inside the collar located on top of the closed end of the first AquaDam.

13.) The closed end of the first AquaDam® is the starting bank for the second SCE AquaDam. To ensure proper installation and functionality of a SCE AquaDam, it is essential to have a starting bank that maintains a higher elevation than the body of the AquaDam. The open end and fill-tubes of the SCE AquaDam® must remain elevated above the full height of the dam along its designated path. It is important to note that an AquaDam® will only reach its maximum height at the lowest elevation point along its designated path.

14.) The workers carefully opened the fill-tubes to insert the discharge hoses into the AquaDam. It is important to note that no fittings should be attached to the ends of the discharge hoses that are being inserted into the fill-tubes. The discharge hoses must extend into the fill-tubes beyond the holes in the collar and down to the closed end. This ensures proper discharge into the AquaDam.

15.) The second SCE AquaDam® has been successfully connected and is currently being filled with water. The collar has been fully extended along the length of the second AquaDam, reaching as far as the collar allows.

16.) Workers were diligent in avoiding large sharp rocks, and any that could not be avoided were covered with dunnage material to prevent damage.

17.) The second 5ft tall SCE AquaDam® has almost reached the ending bank. The closed end of an AquaDam® must meet the ending bank square. Workers will need to put a turn where the roll is.

18.) The second SCE AquaDam® has been successfully unrolled and secured at its ending bank by workers to prevent any movement. Can you discern the difference in water depth between each side of the AquaDam?

19.) Workers have secured the closed end, which is still partially rolled up, to an anchor. This precaution ensures that as the dam continues to fill, the end will remain stable and in place.

20.) Looking upstream at the 5ft tall AquaDams as they finished being filled with water. The Merced River has successfully been diverted.

21.) Once the second SCE AquaDam® was fully filled with water, workers proceeded to wrap up and secure its fill tubes to prevent any water from draining out.

22.) The workers have completed filling the first AquaDam® and are now securing its fill tubes.

23.) In this image, we can observe the open end and one of the fill-tubes for the initial SCE AquaDam. It is important to note that the open end has been securely fastened with rope to prevent any movement.

24.) Looking downstream at the 5ft tall AquaDam® cofferdam system as it is diverting the Merced River.

25.) Approximately one month later, the workers have successfully decommissioned the Cascades Diversion Dam. Now, it is time to remove the 5ft tall AquaDams.

26.) The work area was re-watered by workers to ensure uniform water depths on both sides of the AquaDams. Subsequently, workers utilized ratchets and brackets to efficiently re-roll the AquaDams as they were being drained of the water inside.

27.) Lots of material were moved during the decommissioning of Cascades Diversion Dam.

28.) Workers inserted suction hoses, without fittings, into the fill tubes to extract water from the SCE AquaDam.

29.) In this photo, workers are seen re-rolling the AquaDam® at the roll end using ratchets and brackets. The process of re-rolling is tedious and meticulous, as the more water that is removed, the more efficient the removal of the AquaDam® becomes. It is important to note that all the water contained within the AquaDam® should be discharged back into the river.

30.) In order to effectively re-roll an AquaDam, it is crucial to have a durable and sufficiently long beam. Skilled workers strive to tightly re-roll the AquaDam® to maximize water removal process.

31.) Once the body of the AquaDam® had reached the water level, workers disconnected it from the connection collar and carefully laid the fill-tubes into the river. As the workers rolled up the AquaDam, the water was able to flow out through the fill-tubes and back into the river.

32.) The workers have successfully re-rolled one AquaDam, and now it is time to move on to the next one.

33.) The workers successfully removed the second AquaDam, mirroring their efficient work on the first one. Congratulations to all involved for a job well done!

5ft Tall Single Closed End (SCE) AquaDam® Cofferdam System, Merced River, River Diversion, Cascades Diversion Dam Removal, Yosemite National Park, U.S. National Park Services