1.) The Retamal Levee System in Hidalgo County, Texas underwent a comprehensive flood simulation test on a specific section, utilizing an AquaDam. The international Boundary and Water Commission (IBWC) purchased a 16ft tall 33ft wide 234ft long double open end (DOE) AquaDam® to make a temporary pond.

2.) A suitable foundation was prepared for the AquaDam® by raising the ground surface for the AquaDam® at its full height to reach the levee crest.

3.) AquaDams are delivered in a rolled-up form, similar to a carpet roll on a wooden beam. They are wrapped in a protective covering and include lifting ropes or straps for easy transportation.

4.) The 16ft tall DOE AquaDam® has been delivered to its starting bank. The open ends and fill-tubes of a DOE AquaDam® must be elevated higher than the full height of the dam along its given path. An AquaDam® will only reach its full height at the lowest elevation along its given path. When full, the top of an AquaDam® will be level and the bottom lays on the contours of the ground creating a seal.

5.) Workers remove the protective wrapping and lifting ropes.

6.) Several feet are unrolled to expose the fill-tubes.

7.) The excavator has brought the roll closer to the crest of the levee, which is where the AquaDam® will start from.

8.) Workers carefully unroll the AquaDam® down its starting bank to the foundation that was just made.

9.) Typically, an AquaDam® would be launched from its starting bank and worker could begin to fill it with water. For this situation, workers will unroll the entire length of the AquaDam® and position it prior to filling it with water.

10.) It was important that the AquaDam® be unrolled onto a flat surface, otherwise the water that goes inside will want to pull it down the slope.

11.) Workers take their time to unroll the AquaDam® out in the correct location the first time.

12.) Workers push on the roll while the excavator gently uses the bucket to help.

13.) The 16ft tall AquaDam® has been unrolled to the first turn.

14.) Workers have to unroll and twist the roll end, so that more material is pleated on the inside of the turn.

15.) The roll is unrolled while the outer side of the roll swoops around and the inner side of the roll stays in place.

16.) As the AquaDam® is unrolled workers do their best to pull it and keep it in place.

17.) The beam that the AquaDam® came rolled up on appears to have broken, just before the dam was unrolled.

18.) Workers must lift the material to get the beam out.

19.) The excavator lifts the material while workers pull on a rope attached to the beam, to pull it out of the material.

20.) With the beam out, workers pull the other open end and fill-tubes up the levee.

21.) Now that the AquaDam® is unrolled, workers must try to maneuver the material to allow water to pass through easily.

22.) The outside ends of the corners must be pulled out and the inside corners need to be pleated.

23.) Workers pull the open end up the levee to get it into place.

24.) The AquaDam® was filled with air first to help realign all of the layers, in place. Larger AquaDams have multiple layers.

25.) Workers have six discharge hoses running into the AquaDam® to fill it with water.

26.) A worker waits at the inside corner to make sure that the water flows through the pleats, correctly.

27.) As the AquaDam® was filled with water, workers drilled holes to place sensors on the levee, for the flood simulation testing.

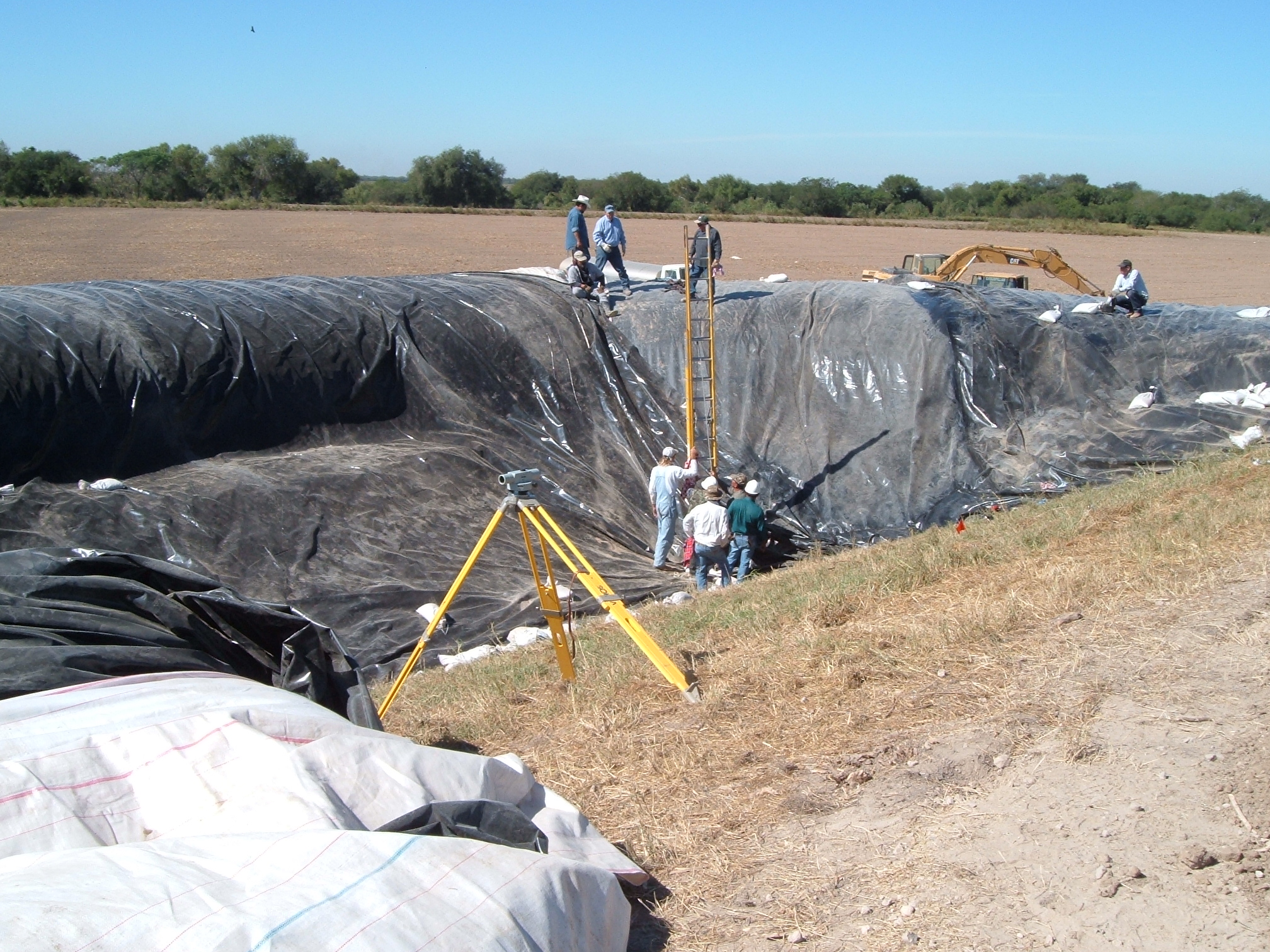

28.) Pond liner material was brought in to lay over the AquaDam® and fill material used as a foundation.

29.) The liner material needed to be unrolled and cut to specific lengths first.

30.) Non-abrasive fill material was laid on parts of the AquaDam® so that the excavator could track over the dam without damaging it.

31.) Another view of the excavator laying non-abrasive fill on the AquaDam.

32.) Here are some of the sensors that workers installed into the levee for the flood testing.

33.) The DOE AquaDam® is in place and filling. This AquaDam® was laid in a horseshoe/”U” shape configuration.

34.) Non-abrasive fill was pushed up to the outer perimeter of the AquaDam, to help keep it in position as it was filled.

35.) The fill was pushed right up against the AquaDam® around the outer perimeter.

36.) Now that the 16ft tall AquaDam® is nearly full, workers begin to layout the pond liner.

37.) The liner needed to be unrolled, unfolded, and then laid into place.

38.) The liner extended out and over the fill berm pushed up against the AquaDam.

39.) Only the glass lined sloped wall of the levee was left unlined, so that water would be able to infiltrate though that side.

40.) Workers will fill this area with water as a simulation for a design storm flooding event.

41.) The simulated flood water was to only infiltrate through the grassed section.

42.) Workers placed sand bags atop the liner at set intervals to help to keep it in place.

43.) The temporary pond, constructed with a 16ft tall AquaDam, from an elevated vantage point.

44.) A worker who was impressed how quick and easy the AquaDam® was installed.

45.) Now that the pond liner material has been laid, workers must secure and seal it.

46.) The edges of the liner must be overlapped and sealed.

47.) A special tape was used to seal the two ends of the liner together.

48.) The special tape was heat activated and so workers used heat guns.

49.) Now water can be added to the temporary pond.

50.) Staff gauges were installed so that workers could monitor the water depth in the pond during the testing process.

51.) A close up of the gauges used to measure the water depth in the temporary pond.

52.) Fantastic job AquaDam!

16ft Tall 33ft Wide 234ft Long Double Open End (DOE) AquaDam, Temporary Pond Creation, Retamal Levee Flood Test, Flood Simulation Study of Retamal Levee, International Boundary and Water Commission (IBWC), US Army Corps of Engineers (USACE), Horseshoe/”U” Shape Configuration