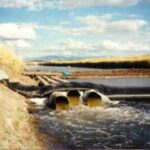

This image shows the intake side of the flume pipes, where water is directed through the AquaDam® system. The installation demonstrates effective water management and flow control.

This image provides a clear view of the downstream end of the three flume pipes, showing their placement and function within the AquaDam® system.

This downstream view highlights the work area, now completely dewatered. The AquaDam® system is effectively maintaining a dry environment, ensuring optimal conditions for construction or excavation.

This upstream view showcases the AquaDam® cofferdam system fully operational. The work area is clearly dewatered, demonstrating the system’s effectiveness in controlling water flow and maintaining a stable, dry environment.

To facilitate trenching for natural gas pipeline placement, the flume pipes were positioned closely together, providing adequate clearance for the excavator.

This photo shows the starting bank for the 4ft tall downstream SCE AquaDam®. A properly constructed starting bank is essential for SCE AquaDam® installations, as it ensures that the open end and fill tubes remain at a higher elevation than the main body of the AquaDam®. To function correctly, the open end and fill tubes must be positioned above the dam’s full operating height along its intended path. It is important to note that an AquaDam® will only achieve its full height at the lowest elevation point along its alignment.

In a swift six-hour operation, two single closed end (SCE) AquaDams® were deployed in the Pit River near Alturas, California, effectively creating a dry work area. The upstream dam, measuring 6ft tall, 13ft wide (fully filled), and 100ft long, impeded river flow, allowing water to pool and channel through three 24in flume pipes. A smaller, 4ft tall, 9ft wide, 100ft long SCE AquaDam® was strategically placed at the downstream end. Sandbags were utilized between the flume pipes on both AquaDams® to ensure a complete seal.

Two 100ft Long Single Closed End AquaDams®, Pit River, Natural Gas Pipeline Installation, Flume Pipe Diversion, Staggered Configuration