Under Mississippi state environmental regulations, a project of this scale would not have been permitted to proceed had it resulted in significant ecological disruption. Traditional methods, such as sandbags, would have been ineffective in controlling water flow and preventing sediment release, while sheet piling was evaluated as cost-prohibitive and logistically impractical for the site conditions. Thanks to the efficiency, environmental compatibility, and rapid deployment of the AquaDam® cofferdam system, the pipeline crew was able to begin inspection and maintenance work the very next day. The system not only met regulatory requirements but also delivered outstanding performance under challenging river conditions.

With the de-watering process well underway, the AquaDam® cofferdam system continues to perform exceptionally. Structural integrity has remained consistent, and the volume of seepage observed has been minimal to nearly nonexistent. The clarity of the water on the right side of the AquaDams® speaks for itself; demonstrating just how effective the system is at isolating the work area without disturbing the surrounding environment.

During the de-watering process, several recreational users on personal watercraft passed by the work area. Thanks to the AquaDam® cofferdam system, the construction zone remained fully contained, preventing sediment or turbidity from entering the main river channel. As a result, nearby recreational activities continued uninterrupted, and the river remained clear—underscoring the environmental benefits of using a water-filled cofferdam system in sensitive or high-traffic areas.

After the excavator completed pushing the fill material snugly against the AquaDams® to enhance their structural support, the pumps were primed and ready to initiate the de-watering process.

Had the excavator punctured one of the AquaDams®, it would have negated hours of careful installation and preparation. When working in or near water with heavy equipment, precision and finesse are essential. While AquaDams® are manufactured to contain and control many gallons of water, they are not designed to withstand direct impact or abuse from sharp tools attached to machinery such as a 50-ton excavator. Strict coordination between ground personnel and equipment operators is critical to maintaining the integrity of the system.

The worker wearing the white hard hat was responsible for directing the excavator operator during the placement of the nonabrasive fill material. It was critical that the teeth of the excavator bucket did not come into contact with the AquaDam®, as this could compromise the dam’s integrity. The operator was instructed to carefully drop the fill material in the designated location and then gently push it into the side of the AquaDam® to provide the necessary structural support without causing damage.

Before de-watering operations commenced, the installation team determined that additional structural support was necessary to ensure the AquaDams® remained stable under changing hydraulic conditions. As a precaution, nonabrasive fill material available on-site was placed along the inner perimeter of the AquaDams® to provide reinforcement. This measure enhanced stability and reduced the risk of movement or shifting during water removal.

A close-up view of the 90-degree connection reveals that the fill-tubes have been strategically elevated to mitigate leakage. Additionally, one discharge hose remains inside one of the fill-tubes, providing an immediate means to top off the AquaDam® if necessary.

Throughout the project, water pumps were strategically placed in kiddie pools, marked in red, to prevent any potential fuel spills from contaminating the river. This precautionary measure ensured that fuel and other hazardous materials did not come into contact with the river’s water, protecting the surrounding environment from contamination.

The 4ft tall SCE AquaDam® is unrolling and being filled with river water. Because the connection collar was positioned at a 90-degree angle before attachment, the final section of cofferdam can be deployed without requiring any additional turning.

Because the 6ft tall AquaDam® was installed directly atop a smaller connection collar, the subsequent 4ft tall SCE AquaDam® can now abut it perfectly without any compromise in support.

As the 6ft tall AquaDam® neared the end of its unrolling, a connection collar for the next dam was positioned at a 90-degree angle to the current unit and at it's closed end. This setup allowed the end of the 6ft tall AquaDam® to unroll smoothly over the collar.

The water pressure within an AquaDam® increases with its height due to the greater water column exerting force on the structure. As a result, larger or taller AquaDam® units require additional workers and ropes to effectively secure and stabilize them during installation.

During the installation of the 6-foot-tall AquaDam®, one group of workers was responsible for holding the ropes that controlled the unrolling of the dam, while another group positioned themselves in front of the roll to ensure stability and control. Throughout the process, it was crucial to maintain the AquaDam®'s internal head pressure and to unroll the unit slowly. This careful approach ensured that workers could maintain full control over the AquaDam® as it was deployed, minimizing the risk of instability and ensuring proper positioning.

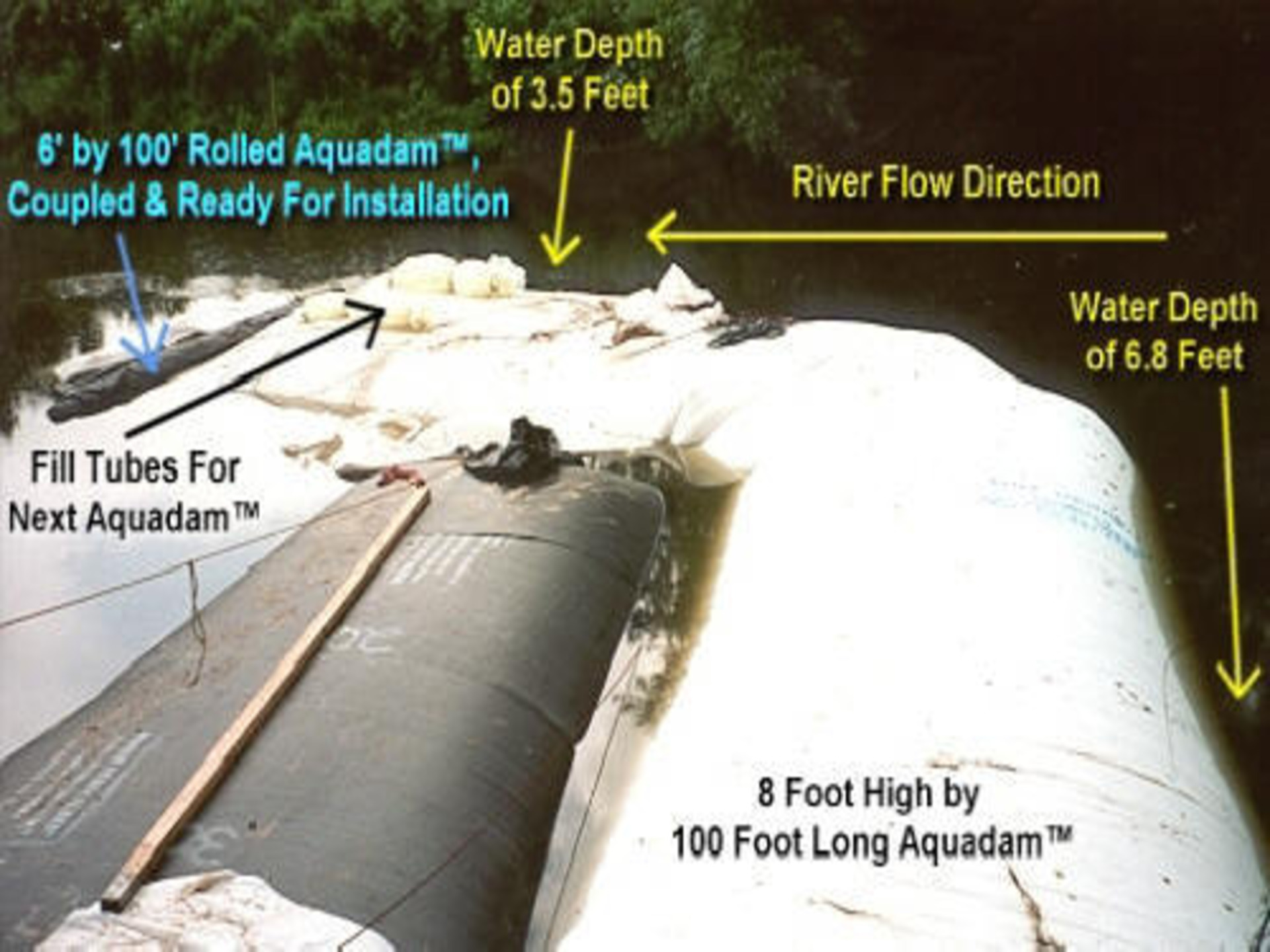

As a result of the cofferdam system’s installation, the river’s width has been reduced to at least half of its original span. Consequently, the water velocity along the outer edge of the AquaDam® has increased significantly. Additionally, the water depth upstream of the AquaDam® has risen, reflecting the changes in flow dynamics caused by the temporary diversion and containment of the river’s current.

The fill-tubes from the subsequent 6ft tall SCE AquaDam® were inserted through the connection collar of the larger, 8ft tall second AquaDam®. This connection collar is attached to the closed end of the 8ft tall AquaDam®, ensuring a secure and proper integration of the two units.

The next stage involved installing an 8-foot-tall, 17-foot-wide (fully filled), 100-foot-long Single Closed End (SCE) AquaDam®. This unit was deployed alongside the previously installed 6-foot-tall SCE AquaDam®, which served as a support structure. The 8-foot AquaDam® was unrolled to match the length of the support dam and then turned downstream at its end to continue forming the perimeter of the cofferdam system. The presence of the support dam significantly reduced the impact of the river’s current, allowing the larger AquaDam® to be installed with greater ease and control. With diminished hydraulic resistance, the team was able to position the unit more efficiently and with improved safety.

The first step of the project involved the installation of a 6ft tall, 13ft wide (fully filled), 50ft long single closed end (SCE) AquaDam®. This initial unit was deployed to divert the river’s current toward the opposite bank, beginning the process of isolating the work area. Functioning as a “deadman,” this AquaDam® also provided anchoring support for the subsequent installation of a larger AquaDam®, which was configured to bend around the end of the first unit to create a continuous watertight barrier. Due to the river’s depth nearly exceeding the height of the first AquaDam®, it was critical to maintain consistent internal water pressure (head) during installation to ensure the structure’s buoyancy and stability. To assist with controlled deployment, three ropes were used to manage the roll, allowing workers to safely position the AquaDam® under challenging hydraulic conditions.

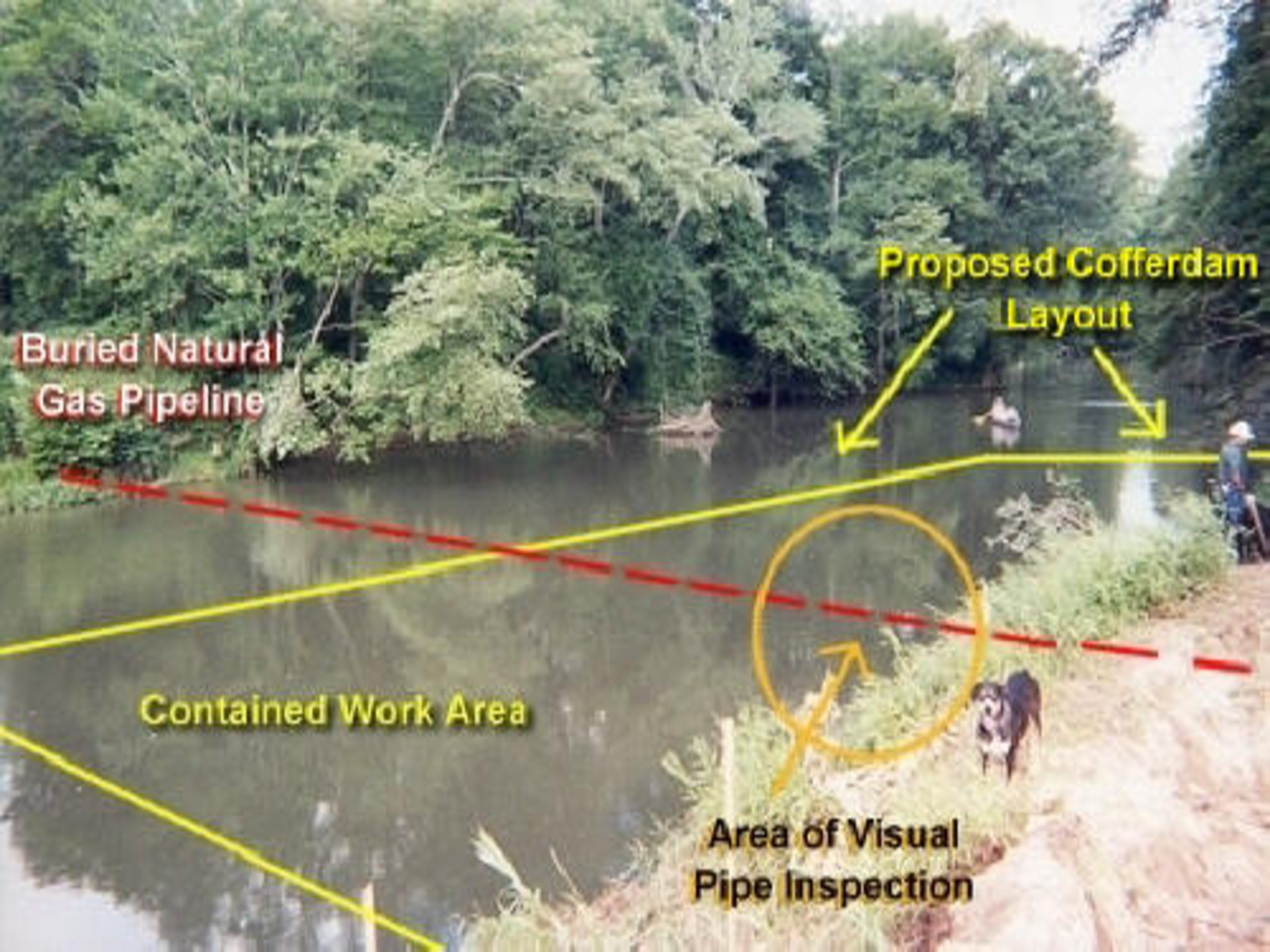

The proposed design utilized AquaDam® units to create a temporary cofferdam system that would isolate the work area and divert the river’s flow around the site. This layout was specifically engineered to maintain continuous river flow while providing a dry and stable environment for pipeline inspection. A key factor in selecting the AquaDam® system over traditional earthen fill methods was water quality protection. The AquaDam® offered a significantly lower risk of sediment disturbance and contamination, aligning with environmental best practices and regulatory requirements for work in sensitive aquatic environments.

The objective of this project was to de-water a specific section of riverbank in order to facilitate a visual inspection of a 32-inch diameter natural gas pipeline as part of a scheduled maintenance program. The worksite was located along the Bogue Chitto River in McComb, Mississippi—an area known for its popularity as a recreational destination during the summer months. Due to the river’s continuous flow and ecological significance, the de-watering process required a controlled, non-invasive solution that would allow safe access to the pipeline while minimizing disruption to the surrounding environment.

Single Closed End (SCE) AquaDams®, Bogue Chitto River, River Diversion, Williams Transco Pipeline, Pipeline Repair, Horseshoe/”U” Shape Configuration