Three single closed end (SCE) AquaDams were used to divert the Rogue River and construct a boat ramp in eastern Grants Pass, Oregon. To ensure proper installation and functionality of a SCE AquaDam, it is essential to have a starting bank that maintains a higher elevation than the body of the AquaDam. The open end and fill-tubes of the SCE AquaDam must remain elevated above the full height of the dam along its designated path. It is important to note that an AquaDam will only reach its maximum height at the lowest elevation point along its designated path.

Ensuring a completely dry work area was not necessary for this project. Workers did not require a dry space to position the large prefabricated concrete slabs used in constructing the boat ramp. Instead, the swift current at this location of the Rogue River needed to be redirected away from the work area. Once the AquaDam cofferdam system was installed, workers utilized an excavator to excavate material from the river bank and create a suitable foundation for the concrete slabs to lay.

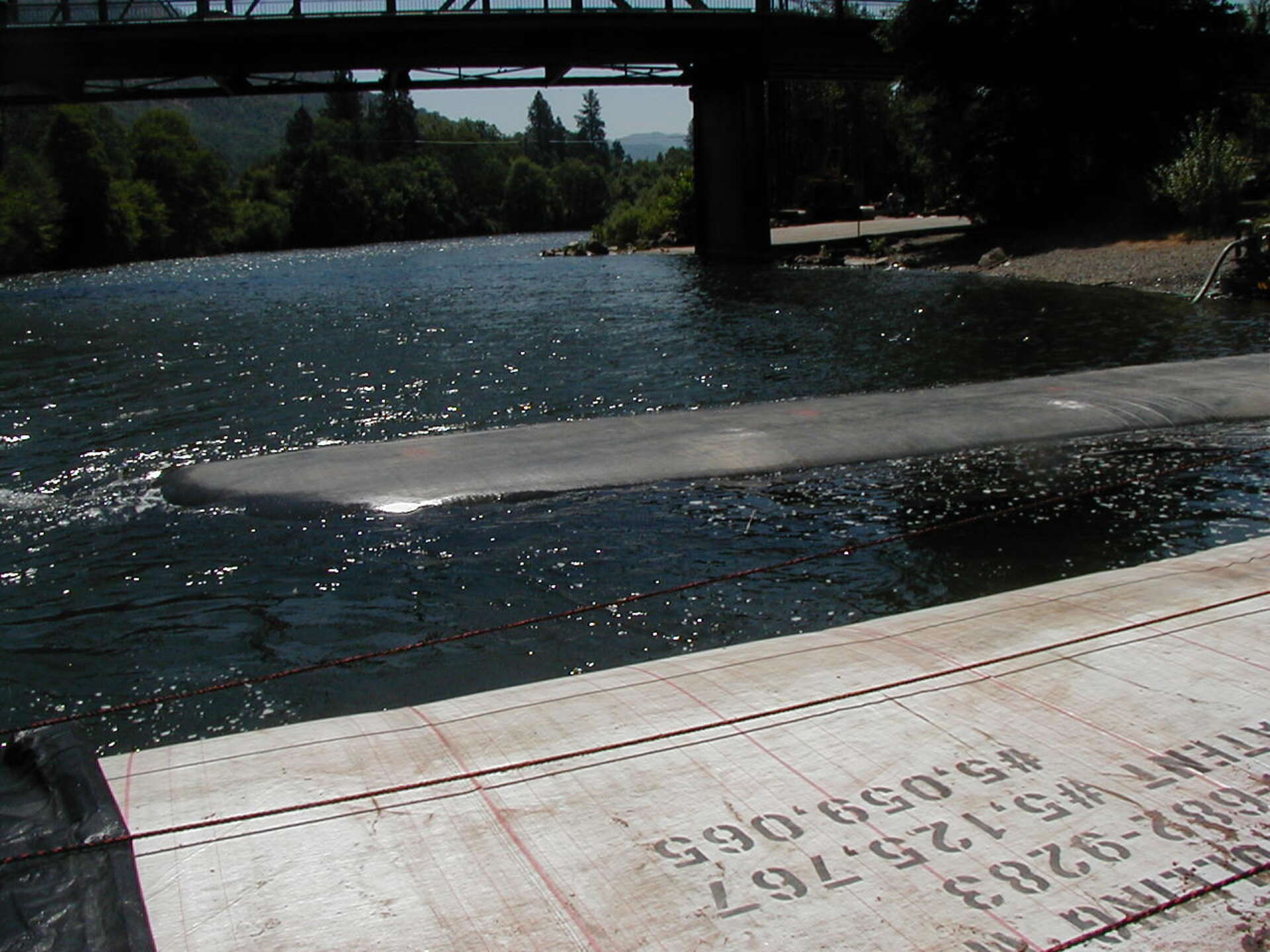

Almost half of the river has been dammed off, diverting all of the water to the opposite side. During the installation process, workers utilized four ropes to assist in controlling the roll end of the AquaDam and prevent it from being pushed downstream. The turbulent white water observed at the closed end of the AquaDam is a result of partially damming off the river. The velocity of the current in the newly constricted channel, as well as the water depth upstream, has significantly increased due to this temporary damming of the river.

Ropes are a crucial part of installing an AquaDam, especially in flowing water. The ropes have been anchored at shore, run under the AquaDam, over top of the roll, and back to workers who control the roll while the dam is being filled with water. The ropes are used to hold back the roll, while the unrolled length fills and gains head above the surrounding water. At this project workers began with a smaller AquaDam to help break up the current. This smaller unit was a 4ft tall 9ft wide 60ft long SCE AquaDam, which was placed upstream of the main AquaDam, on the left.

In this photo we can see the 4ft tall SCE AquaDam has obstructed the river's current. As the 8ft tall main AquaDam was installed, the upstream pooling depth rose to within inches of the top of the 4ft tall AquaDam.

To provide support for the main AquaDam, a non-abrasive fill material was carefully placed behind it using an excavator. The bucket of the excavator was utilized to secure the AquaDam in place while it was being filled with water. Additionally, a protective black fabric layer was laid along the work area side of the AquaDam to prevent any abrasive materials from damaging the outer layer of the unit.

The first 8ft tall main SCE AquaDam was installed straight out from it’s starting bank. Following this, the second 8ft tall main SCE AquaDam was erected perpendicular to the first, just a few feet away from its closed end. This second AquaDam extended down the river to encompass the designated work area before looping back to shore. The implementation of the 8ft tall AquaDam cofferdam system effectively contained all dirty water within the work zone. Subsequently, workers were able to efficiently create a level foundation for the concrete slabs utilized in the construction of the boat ramp. The workers made a decision to forgo using the connection collar at this particular site because of the heightened current velocity in that area.

The local wildlife displayed curiosity during the installation of the AquaDams, as they decided to use the 4ft tall AquaDam as a platform for investigation and hunting.

At this site, we can observe the junction where the two 8ft tall AquaDams were linked together. The method of connection used here presents difficulties in maintaining water tightness, as there is a high probability of leakage occurring at the rounded ends where the AquaDams meet. The choice to forego using a connection collar to unite the AquaDams at this location was influenced by the unique geographical characteristics of the area and the presence of a swift current.

Looking upstream, can you see how the water depth differs from one side of the cofferdam to the other? The white loose material hanging in the water on the left-hand side of the closed end of the first 8ft tall AquaDam is the connection collar, which ultimately went unused. The swift water flow posed a safety risk for workers attempting to make a connection at the closed end of the first 8-foot-tall SCE AquaDam.

This is the closed end of the second 8ft tall SCE AquaDam, after it has been secured against the shoreline or its ending bank. Workers secure the roll to prevent it from unraveling once it reaches the ending bank. The water at the bank is quite shallow. In contrast, at the other end, in the middle of the river, the water depth was approximately 6 feet deep.

This photo was captured from the old Depot Street Bridge, located just upstream of the project site, offering a downstream view of the cofferdam. Throughout the project, recreational watercraft were allowed to pass by, as evidenced by the presence of a passing vessel on the right side of the cofferdam. Concerns arose regarding the waves generated by the wake of these passing watercraft, prompting the installation of a 5 MPH speed limit sign.

The client for this project was the Oregon Department of Transportation, who expressed a strong desire to prevent any contaminated water from leaving the project site. The AquaDam cofferdam system proved to be highly effective in containing all the dirty water within the work area, thereby ensuring that the entire river remained unaffected downstream.

The AquaDam cofferdam system, standing at a height of 8 feet, was installed and utilized for a duration of approximately one month. A concrete ramp was poured, extending nearly to the water line. Just prior to reaching the water line, several large prefabricated concrete slabs were strategically positioned, with their reach extending below the water line.

To enhance the stability and durability of the boat ramp, larger rip-rap was strategically positioned on the upstream side, while smaller rip-rap was placed on the downstream side. This design ensures optimal protection against potential erosion and damage caused by high flows during winter seasons. The placement of rip-rap serves as a safeguard to prevent the boat ramp from washing out, thereby maintaining its structural integrity and functionality.

Here is an alternate perspective of the recently completed boat ramp. The contractor opted to utilize a backhoe to assist in the removal of the AquaDam cofferdam system.

A worker who is positioned at the closed end of the first 8ft tall AquaDam, lowers the fill-tubes of the subsequent 8ft tall SCE AquaDam to water level. This action facilitates the controlled release of water from within the dam.

The second 8ft tall SCE AquaDam has been drained to the point where it no longer maintains the required head pressure to remain in place. It can now be effortlessly removed by using a strap wrapped around the roll and closed end. A group of ducks has been diligently patrolling the perimeter of the water-filled cofferdam in a single file line. AquaDams are not only environmentally friendly but also offer an ideal habitat for wildlife.

The AquaDam is emptied of water until it becomes buoyant and floats in the surrounding water. This allows for easier removal from the riverbank. As the closed end of the second 8ft tall SCE AquaDam is being pulled onto the bank, the open end and fill-tubes follow, draining the water back into the river. This process ensures efficient and effective removal of the AquaDam from the river.

The excavator positioned at the top left-hand side of the photo is in control of the closed end of the second 8ft tall SCE AquaDam. The removal process must proceed slowly to allow the water inside the AquaDam to drain out effectively. As workers remove the AquaDam, they are essentially separating the material from the water molecules. While some water may still be present, minimizing the water content is crucial to reduce the overall weight.

At this site, workers are utilizing specialized re-rolling brackets, ratchets, and cheater bars to efficiently roll up the AquaDams. The excavator has successfully removed the AquaDams from the river, allowing for the re-rolling process to occur on stable ground. Additionally, the excavator continues to assist in the final stages of rolling the larger AquaDams.

In confined spaces, the AquaDam is re-positioned by equipment, pulling it back 50 feet at a time. Workers then roll up the 50 feet of dam before the equipment pulls it out another 50 feet. This process is repeated until the entire dam is fully rolled up. It is most efficient to have one person on each side of the beam when rolling up a used AquaDam, as long as they have the necessary support equipment such as brackets, ratchets, and a cheater bar.

The workers were in the process of removing the 4ft tall AquaDam in black, while simultaneously draining the first 8ft tall SCE AquaDam in white using pumps.

The 8ft tall SCE AquaDam has experienced a loss of head pressure, causing the river's current to push the AquaDam towards the rip-rap wall built to safeguard the boat ramp. A rope that was initially installed around the closed end of the AquaDam during its installation is now being utilized to extract the unit from the water. As the water inside the AquaDam drains back into the river, the unit is being slowly pulled over the top of itself.

The closed end of the AquaDam was meticulously lifted and pulled over the river bank to be placed on level ground for re-rolling, ensuring its preservation for future projects.

Wonder job everyone!