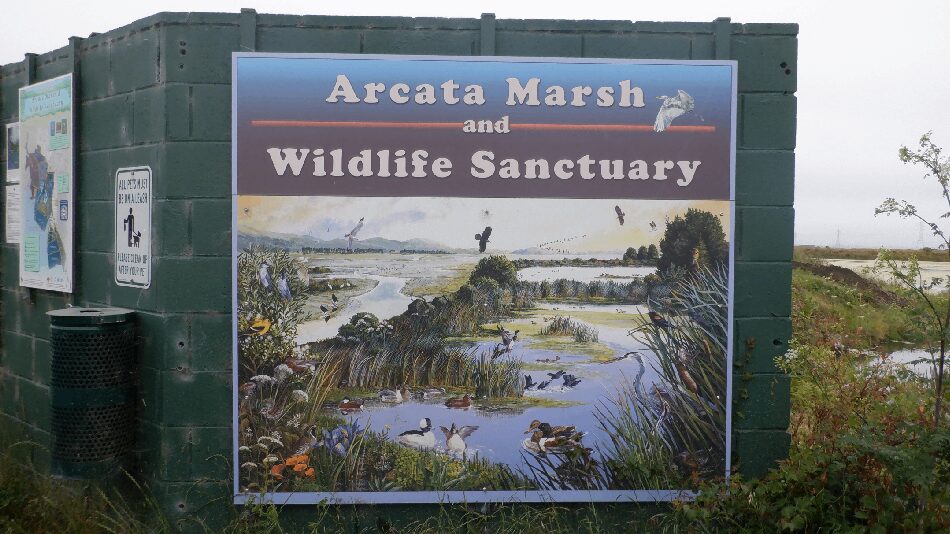

The outfall culvert discharging into Brackish Pond, located within the Arcata Marsh & Wildlife Sanctuary in California, was identified for replacement due to structural deterioration and operational inefficiencies.

A 6ft high, 13ft wide, 270ft long starting bank was built to deploy a single closed end AquaDam®. This bank keeps the open end and fill-tubes elevated above the dam’s body, ensuring proper inflation. An AquaDam only reaches full height at the lowest point along its path.

Prior to installation, the ending bank designated for the 6ft tall AquaDam® required grading to ensure a smooth and stable termination point. This particular AquaDam® unit had previously been deployed at Hauser Marsh, located approximately half a mile south of the current site.

The excavator effectively graded the ending bank, resulting in a smooth and stable surface suitable for AquaDam® installation.

The 6ft tall, 270ft long SCE AquaDam® arrived on-site securely rolled, resembling a large carpet roll, and transported on a dedicated traile

Using an excavator, crews successfully lifted and transported the AquaDam® from the access road to its designated starting bank.

To minimize lateral movement during transport, workers applied tension to both ends of the beam around which the AquaDam® was rolled. This stabilization technique helped prevent excessive swinging and ensured controlled handling throughout the relocation process.

The 6ft tall SCE AquaDam® has been positioned at its starting bank, and the fill-tubes have been pulled into place. The black and white material visible in the foreground, nearest the camera, are the fill-tubes.

Workers are preparing to launch the 6ft tall SCE AquaDam® from its constructed starting bank, ensuring proper elevation and alignment to facilitate effective inflation and deployment.

To position the AquaDam® at the water’s edge, workers manually pushed the rolled unit while the excavator simultaneously applied controlled tension via ropes affixed to the roll. This coordinated effort ensured precise placement along the shoreline for subsequent deployment.

Using pre-inserted pull ropes and coordinated excavator assistance, workers gradually unrolled the AquaDam® across the designated body of water. This controlled deployment ensured proper alignment and minimized disruption to the surrounding environment.

During the unrolling of the 6ft tall SCE AquaDam® across the water body, a full-size pickup truck was strategically employed to anchor and hold down the open end of the unit. This method provided crucial stability, preventing the open end from shifting or moving excessively as the dam was progressively unrolled by workers and the excavator. This technique is a practical example of leveraging available resources on-site to ensure a controlled and successful deployment of a SCE AquaDam®.

Given the short span and minimal to no current in the body of water, workers were able to manually pull the AquaDam® across its intended path before commencing the water-filling process.

To ensure the smooth and continuous unrolling of the AquaDam® across the water, a methodical pull-and-reposition technique was employed. The excavator would pull the dam using a rope until the rope reached its full extension. At that point, a worker would efficiently untie the rope from the excavator's bucket, reposition, and then securely re-tie it to a new point on the AquaDam® roll.

Upon reaching the designated ending bank, workers ensured that the AquaDam® was properly aligned and squared with the bank surface. Precise alignment was essential to maintain structural integrity and optimize sealing performance during the fill process.

To ensure proper seating and perpendicular alignment with the ending bank, the left side of the AquaDam® was adjusted by pulling it slightly upslope. This angled repositioning helped the dam conform to the bank’s contour, improving contact and stability at the termination point.

The 6ft tall 270ft long SCE AquaDam® has nearly unrolled to it’s ending destination.

At the designated ending bank, workers secured the rolled end of the AquaDam® to prevent displacement during the water-filling process.

Workers inserted 3in blue discharge hoses into the fill-tubes of the 6ft tall SCE AquaDam® to fill the unit with water.

As the filling process progresses, the 6ft tall SCE AquaDam® is beginning to develop head, rising slightly above the elevation of the surrounding water.

Workers utilized water trucks carrying potable water to fill the AquaDams® for this project.

The 6ft tall SCE AquaDam® is nearly fully filled and has effectively isolated the outfall from the remainder of the pond.

To prevent backflow and retain the pumped water within the AquaDam®, workers securely tied off and fastened the fill-tubes. This step was critical for maintaining internal water pressure and ensuring the dam remained fully inflated during operation.

Excellent performance demonstrated by the AquaDam® system.

6ft Tall 13ft Wide (fully filled) 270ft Long Single Closed End (SCE) AquaDam®, Arcata Wastewater Treatment Plant, Arcata Marsh & Wildlife Sanctuary, Brackish Pond, Enhancement Wetlands, Tidal Influence, Water Truck Fill, Line Configuration.