1.) This project took place at the Kennedy Space Center in Florida. Our goal was to provide a cofferdam system for workers to de-water an area to isolate and repair a high-pressure pipeline. The pipe goes beneath the Banana River towards the launch pad at Kennedy Space Center.

2.) The project took years of planning, but the two AquaDams were installed, pipeline fixed, and AquaDams removed all within four days. NASA head officials were very pleased.

3.) A warning sign near the job site indicating the type of fluid carried through the pipeline that needed repairs.

4.) The location where the 8ft tall AquaDam cofferdam system will be installed.

5.) Workers have placed the first 8ft tall AquaDam at its starting bank and begun unrolling the first few feet to expose the fill-tubes. This unit is an 8f tall 17ft wide (full) 75ft long double closed end (DCE) AquaDam with a connection collar. A DCE AquaDam does not need an elevated starting bank like a single closed end (SCE) dam, because its fill-tubes are manufactured on top of the unit.

6.) Workers unroll and fill with water the DCE AquaDam. AquaDams are made of light weight flexible materials and will float when empty in deep enough water.

7.) You can see fins in the water which belong to porpoises or dolphins. There were many curious aquatic creatures investigating the AquaDams during this job.

8.) The 8ft tall DCE AquaDam is being filled with water, as workers monitor the roll end and the head that the unrolled length has.

9.) Workers have angled the roll end so that as the unit fills there will be an arch in the AquaDam at that point. The completed cofferdam will make a horseshoe/”U” shape configuration.

10.) The 8ft tall DCE AquaDam continues to fill, while workers adjust the pumps and hold the roll end. Turning the pump(s) filling the fill-tube on the inside of the turn down while making the turn will help.

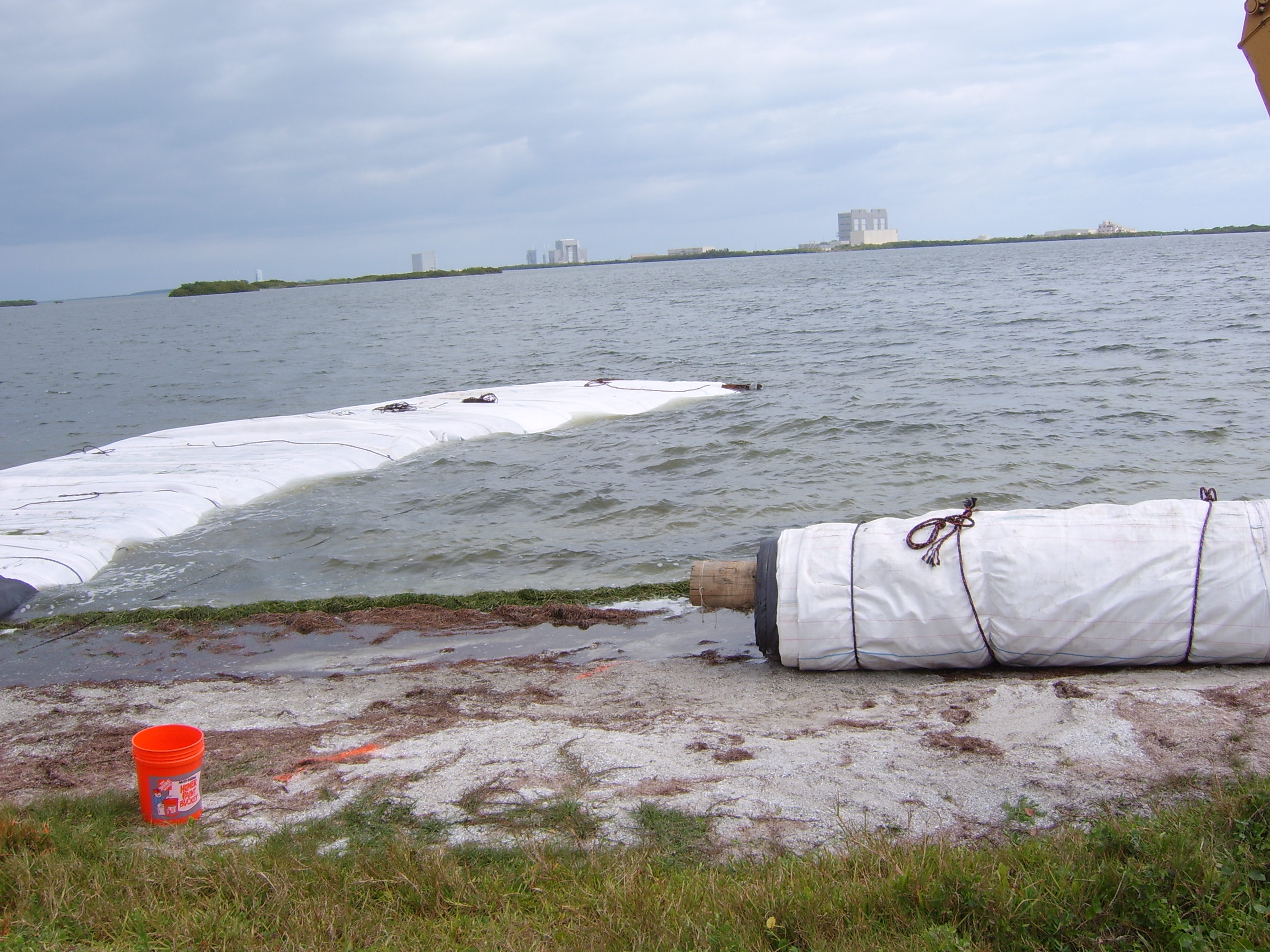

11.) The 75ft long DCE AquaDam has almost completely unrolled to its connection collar. The second 8ft tall AquaDam has been placed at the water edge. AquaDams are shipped rolled-up like a carpet roll on a wooden beam, wrapped in a protective covering, and have lifting ropes/straps.

12.) The second 8ft tall dam was a 278ft long SCE AquaDam. A SCE AquaDam needs an elevated starting bank for its starting point (open end). The open end and fill-tubes of a SCE AquaDam must be elevated higher than the full height of dam along its given path. An AquaDam will only reach its full height at the lowest elevation along its given path.

13.) The DCE AquaDam continues to fill, notice the water has a little wave action going on.

14.) Here we can see the fill-tubes of the DCE AquaDam. They are sticking out between the black and white outer sleeve material with the blue discharge hoses run inside of them. A DCE AquaDam provides its own starting bank.

15.) Ropes have been tied to the DCE AquaDam and anchored back to shore to keep the unit in place while it is filled with water. After the unit is full and has enough head above the surrounding water, the water inside of it will keep it in place.

16.) The 8ft tall SCE AquaDam has had its fill-tubes pulled through the connection collar and the open end laid up on top of the closed end inside of the collar. Now the DCE AquaDam will act as the starting bank for the next dam.

17.) Turns should be made several feet before and/or after connections. Connections with AquaDams are best when made in a straight line.

18.) The 8ft tall SCE AquaDam continues to fill; workers hold the roll end as the dam builds head, unroll a few feet of length, wait for the unrolled portion to build head above the surrounding water again, unroll a few more feet of length, hold the roll tight again, and repeat the process until the dam reaches its ending bank.

19.) Pumps will discharge air along with water sometimes into an AquaDam. The air can easily be walked out, starting at the closed end, and walking the air bubble out towards the fill-tubes.

20.) Here we can see that the SCE AquaDam is approaching its ending bank. The AquaDam should meet the ending at a perpendicular angle.

21.) A rope was tied to the outer end of the beam and back to a piece of equipment to help pull that end around and make the roll end line up correctly with its ending bank.

22.) The SCE AquaDam made it to its ending bank. There were a lot of blocky rocks at the bank, but luckily, they were not sharp and the AquaDam sealed great.

23.) Both AquaDams are installed and now they just need to finish filling and then workers can start de-watering the work area.

24.) Workers can now take a small break while the AquaDam finish filling.

25.) The DCE AquaDam is now full, and the SCE unit is getting close.

26.) Both AquaDams are now full, worker can prepare to de-water and do the pipeline work.

27.) De-watering has begun.

28.) As the water depth drops in the work area, workers move and adjust the suction hoses to deeper holes.

29.) The pipeline has been exposed and now workers can start to access the damages.

30.) Workers inspecting the pipeline needing repairs.

31.) The work area is now pretty much de-watered.

32.) Workers get to digging right away now that the area is drying out.

33.) Workers used shovels while working close to the pipe to so not to damage it.

34.) Everyone hard at work while the work area is de-watered.

35.) You can see the crustaceans growing on the pipe that had to be repaired.

36.) Workers continue to repair the pipeline.

37.) The roll end of the 278ft long SCE AquaDam at its ending bank. Notice the blocky rocks and how dry the area is.

38.) The work area continues to be de-watered. Seepage control is a necessity for all cofferdam systems.

39.) After making repairs workers wrap the pipe with a protective covering.

40.) Workers continue making the necessary repairs.

41.) Now that the pipeline has been repaired and wrapped worker will bury it back into the sand.

42.) Now that the work is done the work area can be re-watered.

43.) It is important to re-water the work area prior to removing an AquaDam. This will equalize the pressure on both sides.

44.) Great job AquaDam!

Two 8ft Tall 17ft Wide (full) AquaDams, Shoreline Isolation, Pipeline Repairs, Banana River, Horseshoe/”U” Shape Configuration, Kennedy Space Center