1.) An AquaDam used as a cofferdam in the Colorado River somewhere in Colorado. The AquaDam was installed in a horseshoe/”U” shape configuration.

2.) The water on this side of the AquaDam has been separated from the water on the far side and the work area has been isolated.

3.) Workers begin de-watering the work area so that they can do the work needed to the boat ramp.

4.) A photo looking at the ending bank of this AquaDam.

5.) Some of the outer sleeve material has separated and the inner material (fill-tube) is protruding out. This is not a deal breaker; the outer sleeve is there to help protect the AquaDam.

6.) Here is another area where the inner tubing has been exposed. The AquaDam is still holding the water inside of it though.

7.) At a closer look, it appears that some of the stitching has come undone at one of the seams.

8.) The work area is de-watering. The AquaDam is doing a great job.

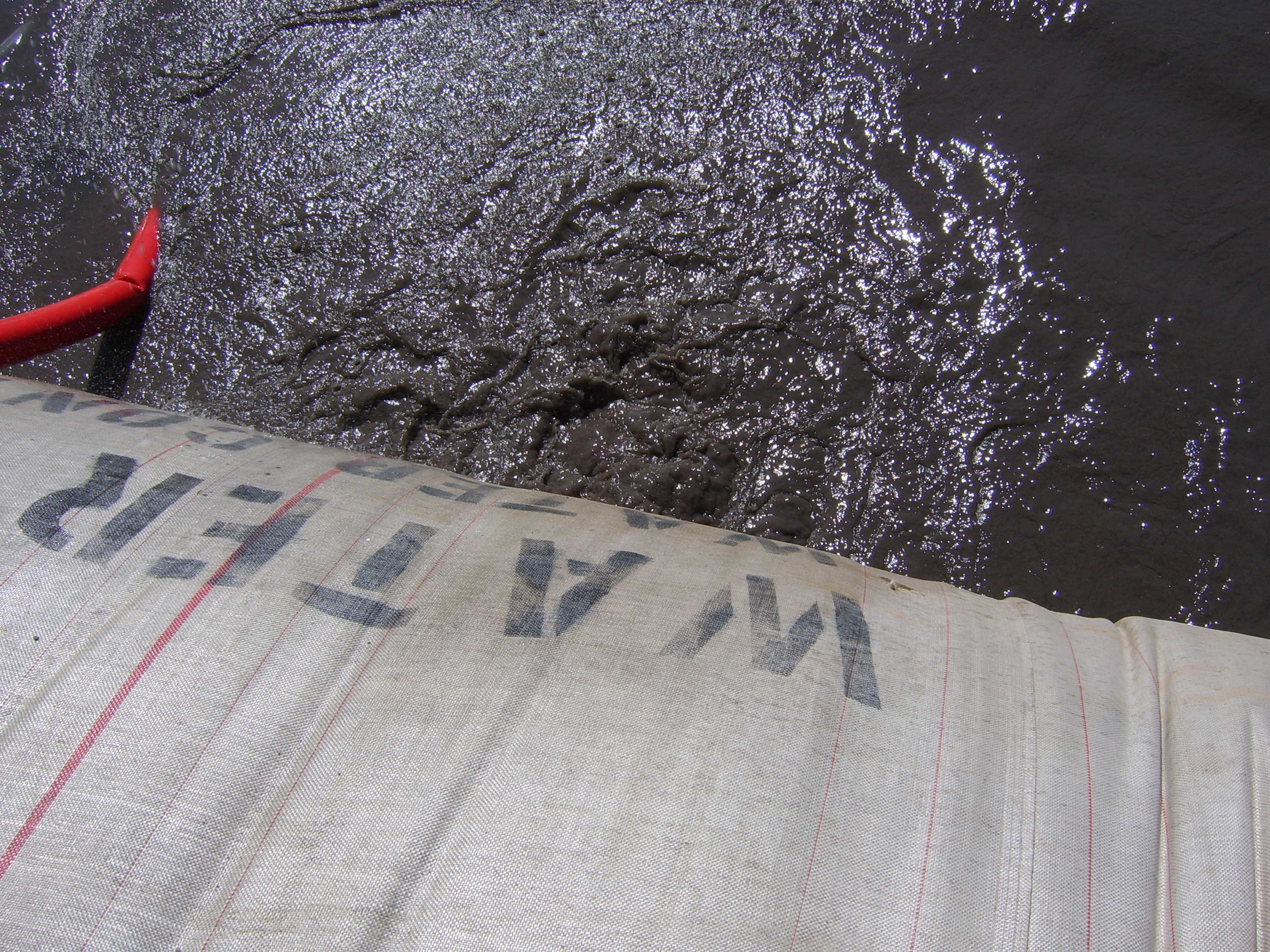

9.) A boil has started, where water pipes under the AquaDam through the riverbed below it.

10.) Most of the time these types of boils will bubble briefly until the AquaDam sinks into the piped channel.

11.) The exposed tubing area appears to be just fine and not affecting the cofferdam function.

12.) Pressure from de-watering may have caused the tubing to bulge out a little more.

13.) The boil seems to be calming down and dissipating.

14.) The boiling action has also moved a little closer to the bank from the first one.

15.) Non-abrasive fill can also be place (very carefully) up against the side of the AquaDam, where the boil is occurring.

16.) Workers have placed tarp material outside of the cofferdam system to try to help prevent the water from piping under the AquaDam.

17.) Great job AquaDam!

Single Closed End (SCE) AquaDam, Horseshoe/”U” Shaped Configuration, Boat Ramp Construction, Colorado River