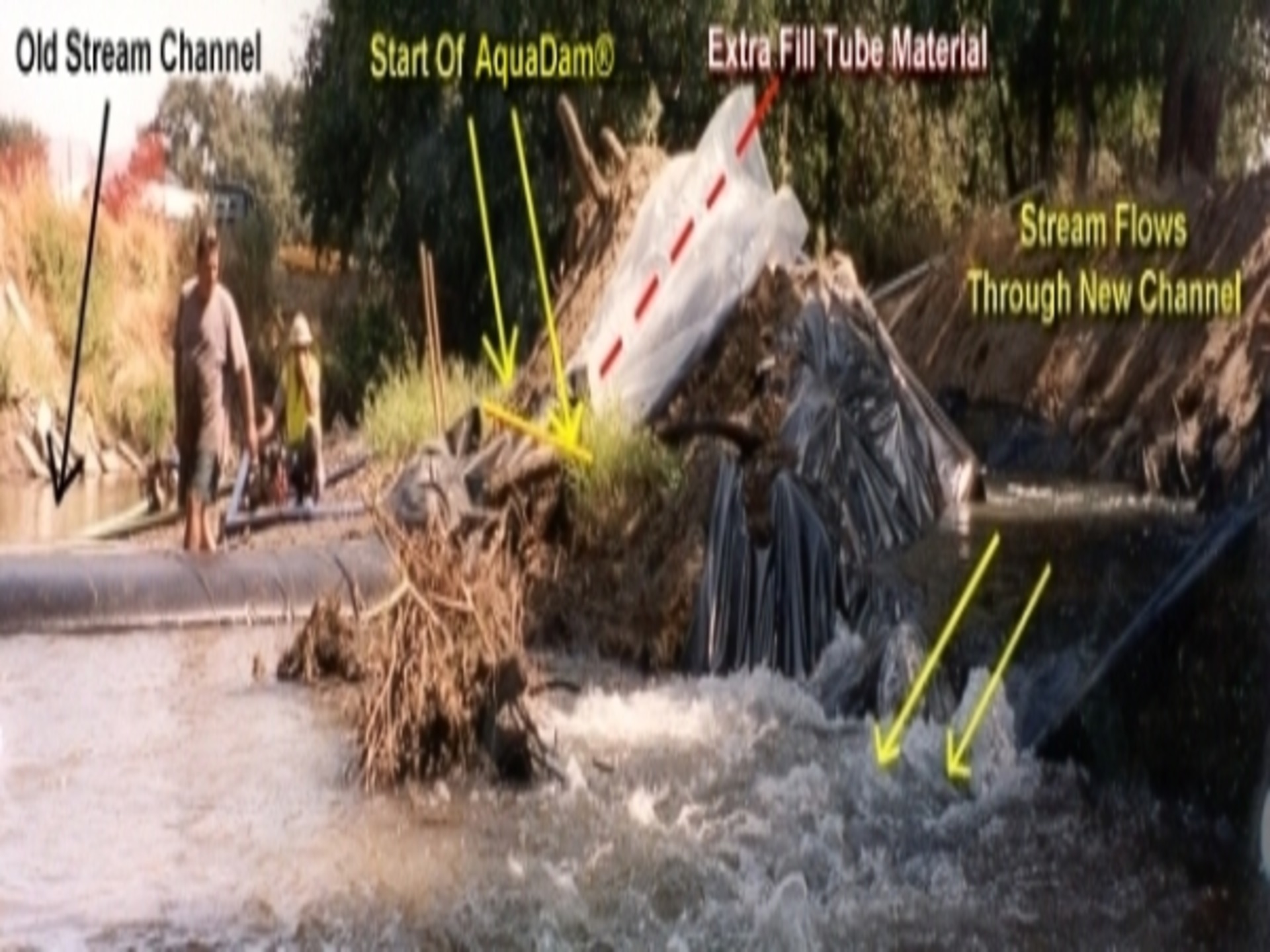

This project involved diverting Antelope Creek in Lincoln, California, through a man-made channel lined with polyethylene sheeting. A 4ft tall AquaDam was installed to block the original creek channel, effectively rerouting the water into the newly constructed diversion channel. With the creek successfully diverted, crews were able to proceed with the installation of a 48in diameter sewage pipeline to support a new housing development.

A 4ft tall, 9ft wide (fully filled), 40ft long single closed-end (SCE) AquaDam was installed with 6mil polyethylene sheeting placed on the upstream side. The sheeting extended approximately 15ft upstream, creating a more effective seal and ultimately eliminating a boil that had formed due to sandy soil conditions and the depth of the water.

A 3ft tall, 7ft wide (fully filled), 40ft long SCE AquaDam was installed at the downstream end of the creek channel. The open end and fill-tubes extended at least 3ft up the starting bank, ensuring that water would not backflow out of the fill-tubes. Proper installation of an SCE AquaDam requires the starting bank to be at a higher elevation than the dam's full height. To function correctly, the open end and fill-tubes must remain elevated above the AquaDam's maximum height along its intended path. It's important to note that the AquaDam will only reach its full height at the lowest point along that path.

Before beginning the diversion, a thorough site analysis was conducted to determine the optimal placement of the AquaDams and the diversion channel. Previously excavated material from the construction of the diversion channel was repurposed to build the starting banks, providing stable launch points for the AquaDams.

To prevent erosion, the contractor was required to line both the sides and bottom of the diversion channel with polyethylene sheeting. In this photo, the upstream AquaDam, the 4ft tall SCE unit, can be seen actively diverting the creek flow into the newly constructed channel.

During installation, workers must take care to prevent the AquaDam from being carried downstream by the current. When empty, AquaDams are made of lightweight, flexible materials that allow them to float in sufficiently deep water, making proper anchoring and control essential during placement.

Discharge hoses have been inserted into the fill-tubes far enough to go down towards the toe of the starting bank. This is a very narrow creek, which did not require use of the entire rolled up length of AquaDam. The remaining footage on the roll is simply tied up and secured from unrolling.

With the AquaDam positioned, it's time to start the pumps. Workers stand behind the AquaDam to prevent it from unrolling prematurely, as the creek’s current constantly pushes against the dam, attempting to carry it downstream. As the dam fills, water inside the fill-tubes generates internal pressure, gradually forcing the roll to unroll. Once a few inches of head are established above the surrounding water, workers release a few feet of length, then secure the roll again. This process is repeated in controlled increments until the AquaDam reaches the opposite bank.

As the AquaDam is filled using water from the creek, workers continue to hold the roll in place to prevent it from unrolling. To keep the AquaDam stationary, the internal head pressure must remain higher than the surrounding water level. As the dam inflates and the upstream flow is blocked, water begins to redirect into the diversion channel, initiating the controlled bypass of the creek.

With the original creek channel nearly blocked, the majority of the flow is now moving through the diversion channel. However, some water still passes behind the AquaDam roll, increasing both the flow velocity and the upstream water depth. Although the AquaDam is only about 3ft from reaching the opposite bank, the crew must pause to hold it in position and allow internal head pressure to build back up. As water levels rise and hydraulic forces increase, the AquaDam must maintain a greater head to remain stable and effective.

As the final section of the AquaDam extends to the ending bank, workers must carefully remove themselves from the narrowing gap to avoid becoming trapped. At this stage, a boil had already developed beneath the AquaDam, caused by a silted-in tire buried under the dam. This issue was later mitigated by placing a piece of polyethylene sheeting across the front of the AquaDam to help seal the area and suppress the upwelling.

The AquaDam is now fully extended and securely abuts the ending bank. The unrolled portion has been placed high enough on the bank to ensure it won't become trapped as the dam finishes filling. The 4ft tall SCE AquaDam is nearly full and has successfully diverted the entire creek flow into the newly constructed diversion channel. With the flow fully bypassed, the crew can now proceed with the installation of the downstream dam.

AquaDams are delivered rolled up, much like a large carpet wrapped around a wooden beam. Each unit is carefully protected with a wrapping and includes lifting ropes or straps for safe and easy handling. For the 3ft tall SCE AquaDam, workers used a utility knife to remove the protective covering and lifting ropes after positioning the dam on its starting bank, ensuring it would unroll in the correct direction. The open end and fill-tubes were pulled up the bank to a point higher than the anticipated full height of the AquaDam to prevent backflow during filling. The outer sleeve of the AquaDam begins at this open end of the woven material.

Two water pumps were set up, with their discharge hoses inserted deep into the AquaDam’s fill-tubes, reaching near the toe of the starting bank. As the AquaDam began to fill, workers held it in place to prevent the creek’s current from pushing it downstream. Proper control during this phase is critical to ensuring a stable and accurate deployment.

The head inside the AquaDam is carefully maintained above the surrounding water level. Workers release a few feet of the dam at a time, stepping back after each release. They then pause to allow the head pressure to build back up before continuing the process. This cycle is repeated until the dam is fully unrolled and reaches the ending bank.

Workers continue this process until the AquaDam is fully unrolled across the creek. For a project of this scale, a minimum of four workers were required: three crew members to hold the AquaDam roll and maintain head pressure inside the dam, and one crew member to operate the pumps.

It's important not to rush the process! The capacity of the pumps dictates the pace of installation, not how quickly the crew can unroll the AquaDam. Proper timing and control are key to ensuring a successful deployment.

The installation of the downstream 3ft tall SCE AquaDam was successfully completed in just 15 minutes, from the moment the pumps were activated to fill the unit. With the AquaDam now in place, the work area is ready for de-watering, allowing construction of the new pipeline to proceed.

The work site has been successfully de-watered by pumping out all the water, allowing excavation to begin. The project required a large trench, with the excavator digging down 15ft to install the sewage pipeline.

Seepage underneath the upstream AquaDam was effectively controlled using a 3in trash pump. Both AquaDams were successfully installed within two hours. Excellent work by everyone involved!