1.) The purpose of this project was to clean up contaminated soil along the shoreline of a man-made channel in the providence of Manitoba North of Lake Winnipeg.

2.) This site was the location where fuel storage tanks were kept and used to fill the heavy equipment that dug out a channel connecting two lakes.

3.) The first day of installation the temperature was -41 degrees Fahrenheit. It took a total of four days to install three 10ft tall 21ft wide 250ft long single closed end (SCE) AquaDams. The three 10ft tall SCE AquaDams were installed in a horseshoe/”U” shape configuration to isolate the contaminated shoreline.

4.) Before the installation could begin, heavy equipment and workers with chainsaws needed to break up and remove the ice in the path of where the AquaDams would be laid.

5.) The first 10ft tall SCE AquaDam has been placed on its starting bank. A SCE AquaDam requires a bank to keep its starting point (open end) higher in elevation than the body of the AquaDam. The open end and fill-tubes of a SCE AquaDam must be elevated higher than the full height of dam along its given path. An AquaDam will only reach its full height at the lowest elevation along its given path.

6.) Ropes have been laid under the AquaDam to pull back over top of the roll and back to workers who will control the roll while the dam is being filled with water. The ropes are used to hold back the roll, while the unrolled length fills and gains head above the surrounding water.

7.) AquaDams are shipped rolled-up like a carpet roll on a wooden beam, wrapped in a protective covering, and have lifting ropes/straps.

8.) Workers continue to clear the path of where the AquaDam will go.

9.) The first 10ft tall SCE AquaDam has been launched from its starting bank and is being filled with water. After the unrolled length has a few inches of head above the surrounding water, workers release a few feet of rope unrolling a few feet of length, then hold the ropes tight again and repeat the process over until the dam reaches its ending bank.

10.) The first 10ft all SCE AquaDam has been completely unrolled to its connection collar on its closed end. The connection collar for this dam was made with white material. It may be hard to see, but workers made a turn in this AquaDam for the desired configuration of the cofferdam. Turning the pumps down that are filling the fill-tube on the inside of the turn (while making the turn) will help. Workers mentioned that they used lots of rope while making this turn. Connection should be made several feet before or after a turn.

11.) The fill-tubes of the first 10ft tall SCE AquaDam can be seen here hanging over the back side of its starting bank. The open end is at the top of the starting bank. Workers have tied this end back to unmovable objects (anchors) to prevent it from moving around during the filling process. After the AquaDam is full of water, the weight of the water will hold the unit in place.

12.) The first 10ft tall SCE AquaDam is now almost full and it is time for the second 10ft tall dam. The AquaDam has several feet of head above the ice of the lake now.

13.) The second 10ft tall SCE AquaDam is in the first dam’s connection collar, it has unrolled its entire length, and is finishing filling. The closed end, where its connection collar is, of the first AquaDam acts as the starting bank for the second unit.

14.) The fill-tubes of the second 10ft tall SCE AquaDam were pulled up through the connection collar of the first dam and laid up on the closed end. Workers used three discharge hoses per fill-tube when filling this AquaDam. Equal pumping power to each side is best, unless making a turn.

15.) It was so cold, that a layer of ice had formed and was floating inside the first AquaDam.

16.) The second 10ft tall 250ft long SCE AquaDam has been filled most of the way. We can see the precut path that was cut for the third 10ft tall AquaDam.

17.) A photo showing the beautiful skyline at the job site, from shore.

18.) Workers bring the third 10ft tall SCE AquaDam closer to the closed end and connection collar of the second dam.

19.) The third 10ft tall SCE AquaDam has been connected through the collar, started filling, and made its turn.

20.) Workers drilled anchors into the ice for ropes to tie off to the AquaDams. These ropes helped hold the AquaDam in place while it was filled with water.

21.) The anchors were also used to help make the turn back to shore.

22.) The third 10ft tall SCE AquaDam has unrolled to its ending bank and now needs to finish filling. The black material to the left of the AquaDam is a silt fence that was required.

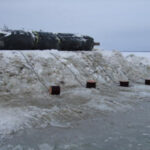

23.) All three 10ft tall AquaDam have been installed and now the work area has been isolated.

24.) Workers needed to breakup and remove all the ice that was left in the work area.

25.) A very large hill of ice was created from the work area. This excavator is working on top of the pile they made.

26.) Here we can see a different excavator and a front loader removing the ice from the work area.

27.) The ice was cut with chainsaws, pulled out with an excavator, and pushed to the hill by the front loader.

28.) Great job AquaDam!

Three 10ft Tall 21ft Wide (full) 250ft Long Single Closed End (SCE) AquaDams, Ice, Lake Winnipeg, Shoreline Isolation, Soil Remediation, Horseshoe/”U” Shape Configuration