This is a 16ft tall 33ft wide 380ft long single closed end (SCE) AquaDam. It has been rolled up on a 12-inch diameter log and loaded onto a flatbed trailer.

A 10ft tall AquaDam was also packed along to be used to divert current flow away from the 16ft tall AquaDam during installation, it was not used. The flow was not that strong at the work site.

Here is the starting bank at this work site, located in Ontario Canada. The 16ft tall SCE AquaDam will be launched between the railroad tracks and telephone poles on the opposite bank.

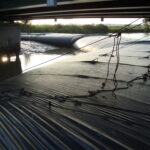

Looking upstream towards the railroad bridge.

Underneath the bridge that needs pier repairs. The 16ft tall SCE AquaDam will start to the right up by the poles.

The AquaDams have arrived at the job site. AquaDams come shipped rolled up like a carpet roll on a wooden beam, wrapped in a protective covering, and have lifting ropes/straps.

A large 60-ton crane was used to disembark the AquaDams. Unfortunately, cranes are only good at lifting so workers will need equipment that can lift, push, and pull.

An excavator was used to move the 16ft tall SCE AquaDam to its starting bank.

Excavators are AquaDam’s best friend. With a skilled operator, an excavator can help unload, unroll, and position an AquaDam. During removal an excavator works well at pulling them out of the water, lifting them to drain, helping re-roll, and loading them back onto a trailer.

The planned starting bank for this SCE AquaDam is behind the ivy-covered telephone pole and the excavator.

One of the two available 6-inch water pumps.

Workers carefully carry the pump down to the starting bank.

This area is the planned starting bank for the SCE AquaDam. A SCE AquaDam requires a starting bank to keep its starting point (open end) higher in elevation than the body of the AquaDam. The open end and fill-tubes of a SCE AquaDam must stay elevated higher than the full height of the dam along its given path. An AquaDam will only reach its full height at the lowest elevation along its given path.

Workers needed to clear the bank of brush and debris. Bank clearing should be done before the installation day to better understand where an AquaDam will be installed.

Workers and the excavator cleared the starting bank for the 16ft tall SCE AquaDam.

The excavator is ready to move the AquaDam now that the starting bank has been cleared of brush and debris.

The roll end was placed in the water while the open end and fill-tubes were pulled up the bank. Ropes were laid down before the AquaDam was moved into place. These ropes will help control the rate at which the AquaDam unrolls as it is filled with water. Two 6-inch pumps will fill this 380ft long AquaDam, one pump per fill-tube.

The excavator used to help install the AquaDam got stuck in the mud, up to the top of its engine compartment.

The AquaDam has been installed in a horseshoe/”U” shape configuration. An AquaDam can be turned during installation in one or more ways. The first way is by slowing down or stopping the pump that is attached to the fill-tube on the "inside" of the turn, or the second by pulling on one side of the log that the AquaDam is rolled around with ropes attached to heavy equipment.

Because the excavator got stuck in the mud, the operator set the pump down as far as he could reach, about 10ft onto the AquaDam. It's sitting on plywood.

Closeup of the excavator in the mud. This operator was a real trooper and continued working even after he got stuck.

The AquaDam is fully installed, and the work area can now be de-watered.

The other side of the cofferdam, looking upstream.

The water in the work area has been completely isolated from the rest of the river.

The unused footage at the end of the roll remains rolled up on the timber. Having additional length is less expensive than not having enough.

The work area is being de-watered.

Overview of the work area, the pier that the AquaDam has surrounded will be repaired.

This mud is soft and deep!

The weight of the water inside a filled AquaDam may displace soft mud.

Soft mud depths must be included with the maximum controllable water depth. A worker should push a measuring rod into the soft mud when measuring the maximum controllable water depth for an AquaDam.

The open end and fill-tubes have been tied off with ropes. This is to prevent the fill-tubes from being pulled sideways or down the bank.

This is a full 16ft tall SCE AquaDam. An AquaDam will only reach its full height at the lowest point along its path. Everywhere else the dam will be shorter in height and slightly wider.

Cutting it close, but the AquaDam made it to the ending bank.

Standing above the ending bank at the downstream end of the AquaDam.

The 16ft tall SCE AquaDam is installed and full. Workers continue to de-water the work area and remove the excavator from the mud.

The excavator was stuck deep in the mud.

Looking upstream at the starting bank of the 16ft tall SCE AquaDam.

Looking downstream at the ending bank of the AquaDam.

Workers have a safety flotation device on the AquaDam because safety is important, especially when working in the water.

The 16ft tall SCE AquaDam has about four to five feet of head above the river.

Standing downstream looking upstream at the horseshoe/”U” shaped configuration AquaDam cofferdam system.

Workers can be seen down in the work area as it is de-watering.

Looking at the ending bank of the AquaDam from the opposite bank of the river.

Since the excavator is stuck, only one pump was usable for de-watering the work area.

Several spools of rope were used to install this AquaDam.

Workers used clever unmovable objects (anchors) to tie off while installing this AquaDam.

After the work area is de-watered repairs can be made to the damaged pier seen in this photo.

A closer photo of the pier needing repairs.

Another great piece of equipment that can be used for installing and/or removing an AquaDam. A rubber tire Telehandler forklift that can lift, pull, and push from many locations.

The work area continues to de-water and now we can start to see some of the riverbed.

The rope by the worker was tied to the bottom of the AquaDam to help position it during installation.

As the work area is de-watered the erosion to the pier can be seen even more.

The AquaDam slightly rolled towards the work area during de-watering.

The portion of AquaDam that went under the bridge was tied off in several places, to help prevent leaning.

Ropes were tied from the bridge to loops attached to the outer layer of 16ft tall AquaDam. These loops are sewn to the outer layer to help with installation tasks such as positioning and restraining.

The loops worked great for tie points along the AquaDam.

Workers discuss the next steps in the plan now that the AquaDam is up, and the work area is de-watered.

Can you tell the water depth difference from left to, right?

Workers check for any fish that may have been trapped in the work area.

Preliminary work can begin on the piers now that the work area is mostly de-watered.

Workers finish up the fish inspection.

A trench was formed by the down-sloping ground towards the right meeting the wall of mud that the AquaDam squished up. This trench made the perfect sump area for seepage. The work area de-watering pumps will have the suction hoses laid in this area.

The blue pump continues de-watering the remainder of the work area.

Full AquaDams are firm enough to walk on safely. Fantastic job AquaDam!

16ft Tall 33ft Wide (full) 380ft Long Single Closed End (SCE) AquaDam, River Diversion, Bridge Pier Isolation, Horseshoe/”U” Shape Configuration