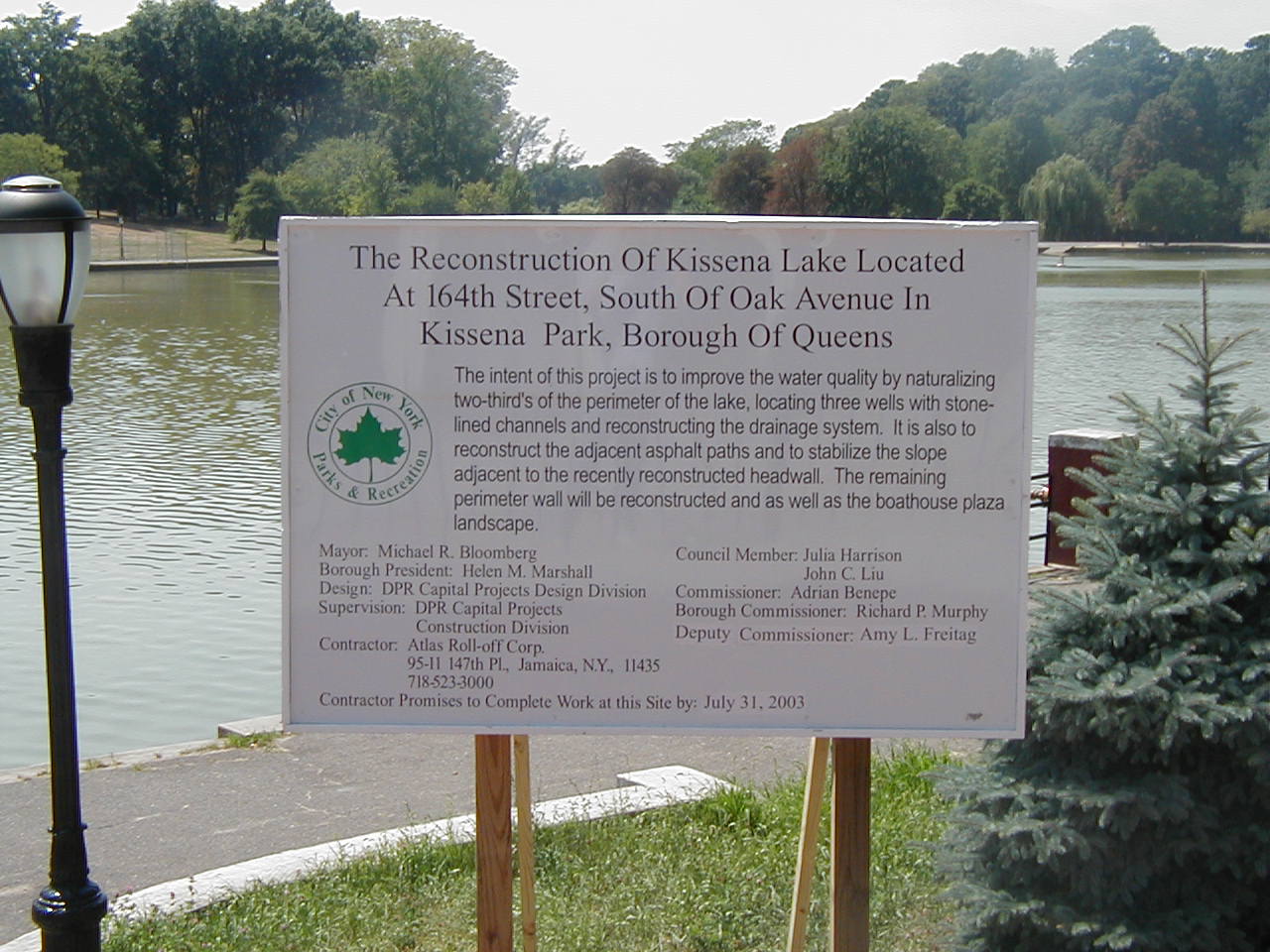

The sign at the job site displaying a brief description of the overall project, taking place.

The yellow rope was used to show the proposed path of the AquaDam cofferdam system being installed.

The starting bank for project needed to be raised to be higher than the maximum height of the AquaDams, so fill dirt was brought in.

The first AquaDam has been launched and is being filled with water. Notice that the starting point (open end) of the AquaDam is up and over the starting bank.

When installing an AquaDam, ropes tied back to anchor points help position the unit as it fills.

A SCE AquaDam must launch perpendicular to the starting bank, otherwise the starting point (open end) may roll down the slope. Here the dam needed to be turned only a few feet out from the starting bank to meet the desired configuration.

The AquaDam continues to fill and unroll across the lake.

The first AquaDam has completely unrolled to its closed end and the remaining material is the connection collar.

Air may get into the fill-tubes of an AquaDam during filling. The air can be simply walked out staring from the closed end and walking toward the starting point (open end).

Here a worker has moved all the air to the starting bank and is pushing it out by leaning into it.

Workers prepare the fill-tubes of the second AquaDam to be put through the connection collar of the first AquaDam.

Workers are pulling the fill-tubes of the second dam up through the connection collar of the first dam.

The fill-tubes are through the connection collar, the collar has been pulled over the second dam a few feet, and the starting point (open end) of the second AquaDam is being set up on the closed end of the first dam.

Discharge hoses are now being installed into the fill-tubes of the second AquaDam. The closed end of the first AquaDam becomes the starting bank for the second AquaDam.

Pumping has begun on the second AquaDam, after making the first connection.

The second AquaDam continues to fill with water.

The second AquaDam has completely unrolled to its closed end and the remaining material is the connection collar.

The third AquaDam is being prepared so that it can be connected to the second AquaDam.

The fill-tubes of the third AquaDam have been prepared and now the unit will be placed into the connection collar on the closed end of the second AquaDam.

Workers pull back the connection collar and pull the next AquaDam into it.

The fill-tubes are through the collar and material of the third AquaDam is being positioned to create a better seal at the connection.

Workers insert the discharge hoses into the fill-tubes. The open end of the discharge hose should go down the slope of the closed end of the AquaDam it is being installed on.

Pumping has begun on the third AquaDam.

The connection collar should be stretched out to get the best connection.

The third AquaDam has completely unrolled to its closed end and the remaining material is the connection collar.

Dirt fill material was place at the starting bank to help address any seepage that may occur where the AquaDam and the concrete wall meet.

The fourth AquaDam has been floated to the end of the closed end of the third AquaDam. AquaDams float on water when they are empty and come in a protective wrapping.

An AquaDam comes on a roll, like a carpet roll, and when installing one a few feet must be unrolled to access the fill-tubes.

Here we can see the starting point (open end) of the fourth AquaDam as workers prepare the fill-tubes to be inserted through the connection collar of the third AquaDam.

The connection collar may need holes cut into it for the fill-tubes to be inserted through. Care must be given when cutting these holes, so that the fill-tubes of the AquaDam does not get cut/punctured.

Workers pull the fill-tubes of the fourth AquaDam through the connection collar of the third AquaDam.

When making a connection it is important to take the time to be sure the two dams will marry up during filling.

The fourth AquaDam is being filled with water.

The fourth AquaDam unrolls as it continues to fill.

The first support AquaDam has been put into the water to be installed.

Dirt fill was dumped at the ending bank to give the AquaDam a better seal to the concrete wall.

The support AquaDam was tied back to the main AquaDam to keep it in place as it fills.

Both the fourth and support dams are filling.

The fourth AquaDam reached the ending bank and continues to fill.

AquaDams are now full and their fill-tubes can be tied up and secured, to prevent leakage.

The starting bank showing the fill-tubes tied closed and starting point (open end) tied back to an anchor.

Any water between a main AquaDam and a support AquaDam should be removed, prior to dewatering the work area.

The AquaDam cofferdam system has been installed.

Over 700ft of Single Closed End (SCE) AquaDams, Kissena Lake, Lake Restoration, City of New York Park and Recreation, Connection Collars.