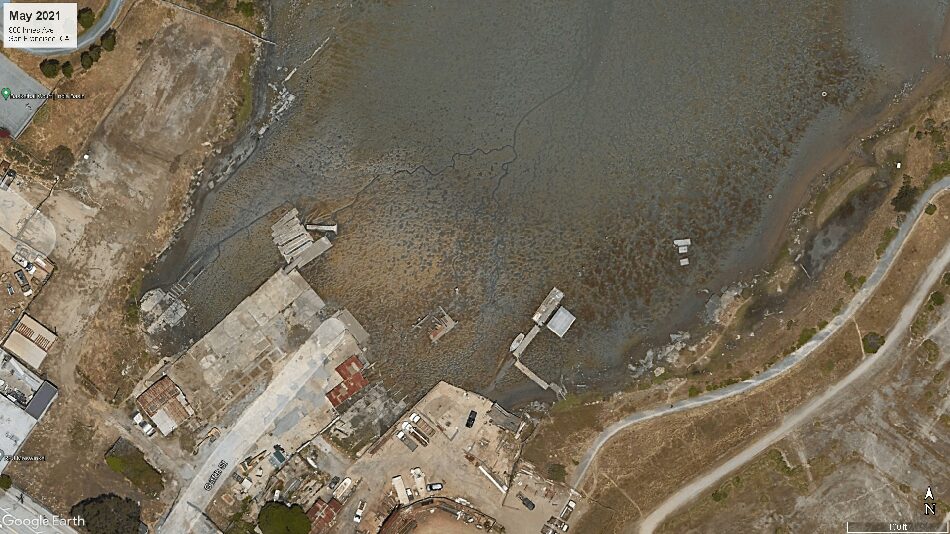

An aerial image of the India Basin area within San Francisco Bay, California, from Google Earth Pro. This image shows where an AquaDam® cofferdam system is scheduled for installation to facilitate de-watering for the cleanup and removal of existing docks.

A view of India Basin, where a 12ft tall, 25ft wide (fully filled), 440ft long double closed end (DCE) AquaDam® is planned for installation. This photo was captured during a low tide event.

The 12ft tall DCE AquaDam® has been delivered to the designated launch site along the bank. For optimal sealing performance, AquaDams® must be launched square to the bank. Each unit is shipped rolled, similar to a carpet, around a wooden beam, wrapped in a protective cover, and equipped with lifting ropes or straps for safe handling during transportation.

Workers have begun filling the 12ft tall DCE AquaDam® using six (6) 3-inch pumps, each placed within its own secondary containment basin ('kiddie pool') to prevent spills. The fill-tubes for a DCE AquaDam® are positioned along the top of the unit, enabling it to self-elevate during filling without the need for a starting bank.

A worker secures a rope around the wooden beam used to roll the 12-foot-tall DCE AquaDam®, allowing the end to be guided into position as the unit makes a necessary turn. This AquaDam® is being installed in a horseshoe or 'U'-shaped configuration. AquaDams® can be turned during installation by various methods, including reducing or pausing flow to the fill-tube on the inside of the curve, or by applying directional force using ropes attached to the beam and pulled by heavy equipment.

The 12ft tall DCE AquaDam® has been fully unrolled and is now in the process of being filled to its designed height. To help maintain its position during filling, ropes were secured to the outer sleeve material and anchored to a fixed object, such as a post or other substantial mass. At this stage, the bay water level is approaching high tide.

The 440ft long AquaDam® did not fully span the distance to the intended termination point on the opposite bank. An initial request was made to terminate the cofferdam against the man-made dock adjacent to the fencing; however, it was later determined that this structure lacks water-tight integrity and would not provide a reliable seal. Upon further evaluation, the beach area to the left of the image was identified as the most suitable termination point for the cofferdam installation.

After installing the 12ft tall DCE AquaDam®, residual water remained trapped at low tide. The AquaDam® settled into the bay mud, showing that a filled AquaDam®'s weight can displace soft sediments, reducing effective height. Soft mud depth must be considered when planning max controllable water depth.

At high tide, water over-topped or bypassed the starting bank from which the AquaDam® was launched, as evidenced by the visibly saturated ground surrounding the structure. This observation suggests that the initial bank elevation or seal point was insufficient to contain peak tidal flow, warranting further evaluation of the launch site's grade and containment strategy.

Workers have begun deploying the support AquaDams® into the water, initiating their installation. These smaller units are crucial for reinforcing the primary cofferdam system.

The support AquaDam® was unrolled to its fill-tubes with the assistance of a rubber-tired telehandler forklift. AquaDams® are constructed from lightweight, flexible materials that allow them to float when empty in sufficiently deep water.

With the fill-tubes of the support dams exposed, workers positioned the first two units adjacent to the 12ft tall main AquaDam®. Following this, the support dams were secured with ropes, and the filling operation began.

Pull ropes are strategically laid within each AquaDam® unit. These ropes play a crucial role in the unrolling process, providing a means to assist in the controlled and efficient deployment of the dam as it's being filled and positioned.

Ropes were secured between the main AquaDam® and the support AquaDams® to hold the support units in place during filling. Workers initially pumped a greater volume of water into the work area side of the support dams, allowing the side adjacent to the main dam to fill last and compress for a tight seal.

When fully inflated, an AquaDam® provides a stable, elevated platform capable of supporting workers, pumps, hoses, and other equipment. This added functionality enhances operational efficiency and accessibility within the de-watered zone.

An aerial view of the 12ft tall AquaDam® cofferdam system fully deployed and filled during low tide.

An aerial view of the 12ft tall AquaDam® cofferdam system fully deployed and filled during high tide. To provide additional structural support, workers installed an 8ft tall DCE AquaDam® alongside the primary unit.

Great job AquaDam®!

June 2021, 12ft Tall 25ft Wide (fully filled) 440ft Long Double Closed End (DCE) AquaDam®, India Basin – San Francisco Bay, Beach Restoration, Tidally Influenced Water, Soft Mud, Horseshoe/”U” Shape Configuration.