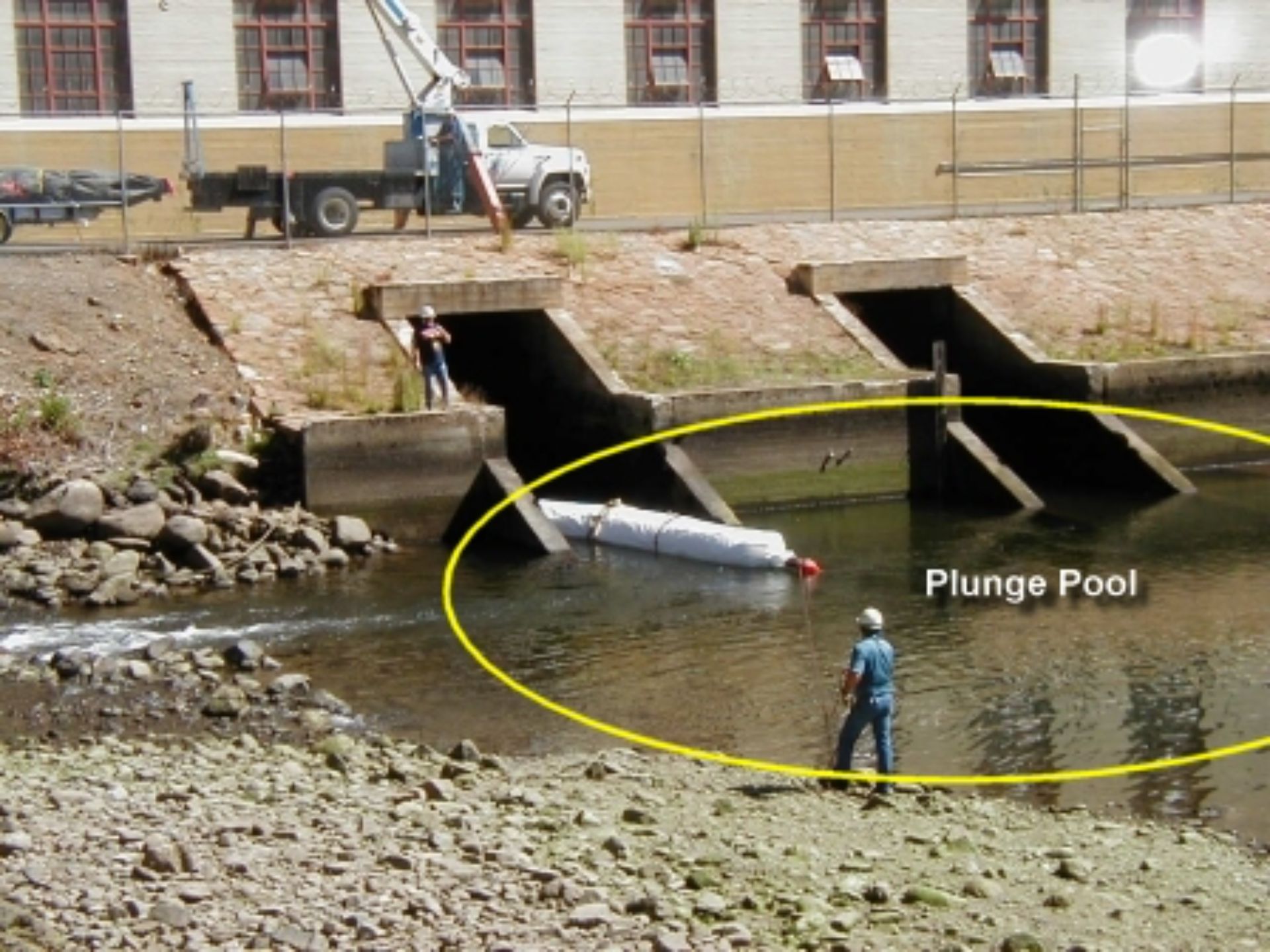

Workers continued to fill the AquaDam, allowing it to unroll across the river and block tailwater from entering the plunge pool. Once the AquaDam was fully installed, de-watering began. The entire project was completed in approximately ten hours, with four of those hours dedicated to placing the flume pipes around the plunge pool.

Since the upstream flow had already been diverted, this installation process was significantly easier. Unlike previous setups, workers did not need to hold back the roll of the AquaDam®, as achieving a larger hydraulic head above the surrounding water was unnecessary. The water depth at this location was 5ft.

Another AquaDam was installed at the downstream end of the plunge pool before de-watering. This photo shows the starting end of an 8-foot tall AquaDam, positioned at its starting bank, with water actively being pumped into it. This downstream dam's purpose was to seal off any tailwater that might enter the plunge pool, thereby separating the work area from the Mokelumne River. Pumping into this AquaDam is ongoing.

The unused length of the AquaDam®, still rolled up, is secured to the bank with a rope to prevent it from falling and unrolling prematurely. Once the unit is fully filled, it reaches its optimal height, ensuring stability and proper function. The pumping time required to complete the filling process for this first AquaDam® was approximately one and a half hours.

The 4ft tall SCE AquaDam® has been successfully installed over the flume pipes, extending from bank to bank across the stream. Some seepage is anticipated, particularly when deployed over large cobble, as depicted in this photo. Water continues to be pumped into the AquaDam® to facilitate its expansion to its full design height of 4ft.

Workers prevent the AquaDam® from joining with the bank until it has developed sufficient hydraulic head above the surrounding water, ensuring it can accommodate the rising upstream flow. The water must pass through the flume pipes and continue downstream, preventing excessive pooling behind the AquaDam®. A 4ft tall AquaDam® is designed to control up to 38in (3ft) of combined mud and water depth.

A worker is positioning a large boulder alongside the downstream end of the AquaDam® to provide lateral support. As water pressure builds from continuous pumping into the AquaDam®, workers step back gradually, ensuring controlled deployment. Patience is essential, advancing too quickly could compromise stability.

During deployment, workers stand behind the AquaDam® to prevent it from unrolling prematurely. As water is pumped into the fill tubes, internal pressure builds and exerts force on the rolled portion of the dam, creating a tendency for it to advance. To control this process, workers use their legs to brace the roll, taking one step backward at a time while allowing pressure to gradually build within the AquaDam®. It is critical that the deployment be carried out slowly and deliberately to ensure stability and proper installation, rushing the process can lead to improper alignment or reduced dam performance.

Water is pumped into the AquaDam's® fill-tubes, located at its open end. The AquaDam® was unrolled over both pipes. As the unit fills, internal water pressure generates head above the surrounding water, causing the roll end to unfurl. AquaDams® are shipped rolled like a carpet on a wooden beam, protected by a covering, and equipped with lifting ropes or straps.

Workers unloaded the 4ft tall, 9ft wide (fully filled), 100ft long single closed end (SCE) AquaDam® and floated it through the plunge pool to its designated installation site. The diversion flume pipes were installed at the proper gradient to ensure effective bypass of the water flow.

A 4ft tall AquaDam® was installed over flume pipes, spanning the stream to isolate the upstream end of the work area from incoming flow. The enclosed area will be dewatered to facilitate work on the powerhouse’s plunge pool.

Two AquaDams®, Mokelumne River, River Diversion, Pacific Gas & Electric (PG&E), Flume Pipe Diversion