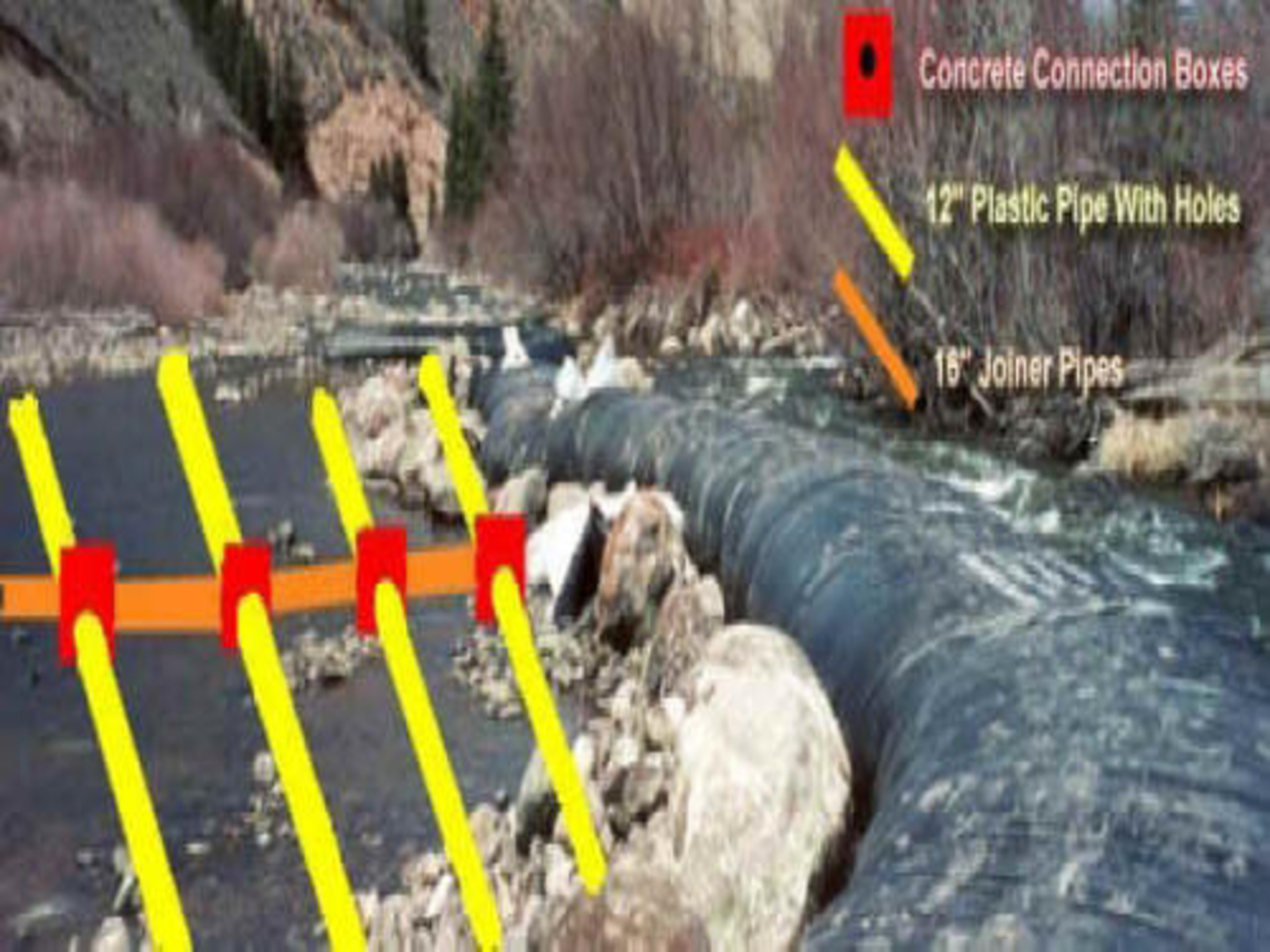

1.) Here we can see some of the components for the proposed water intake system on the Eagle River in Vail, Colorado.

2.) Here is a generic overview of what the water intake gallery should look like after installed.

3.) Examine your work area carefully. Decide where the best position for the AquaDam® to be deployed.

4.) After determining the exact location of where the AquaDam® will lay, large rocks should be removed from the path in the riverbed. The large rocks can be placed on the side of the AquaDam® that will be de-watered to add extra support.

5.) Workers placed the first AquaDam® at it’s starting bank and have already unrolled the roll down the bank. This first AquaDam® is a single closed end (SCE) unit, it’s open end and fill-tubes are the white material to the left of the photo. To ensure proper installation and functionality of a SCE AquaDam, it is essential to have a starting bank that maintains a higher elevation than the body of the AquaDam. The open end and fill-tubes of the SCE AquaDam® must remain elevated above the full height of the dam along its designated path. It is important to note that an AquaDam® will only reach its maximum height at the lowest elevation point along its designated path.

6.) Ropes have been anchored at shore, run under the AquaDam, over top of the roll, and back to workers who control the roll while the dam is being filled with water. The ropes are used to hold back the roll, while the unrolled length fills and gains head above the surrounding water.

7.) The AquaDam® is being slowly released using ropes and with workers holding the roll. The objective is to release the dam in a controlled manner, ensuring there is enough head pressure inside to prevent the current from pushing the AquaDam® downstream. As the dam diverts the current, the water depth upstream will rise, and the velocity of the current passing the dam will increase.

8.) When working in water it is important not to get in a hurry, allow the pumps do the work for you. Here the excavator is on standby to assist with any heavy lifting or rock removal.

9.) To control the unrolling speed of the AquaDam, the excavator's bucket can be positioned behind the roll. This will help prevent the AquaDam® from unrolling too quickly. In the event that ropes need to be loosened to adjust their positioning, the excavator can also assist with this task.

10.) A connection collar is currently being installed at the closed end of the 6ft tall SCE AquaDam. This collar will serve to connect the 4ft tall AquaDam® (not depicted in this photo) to the end of the 6ft tall AquaDam.

11.) The first SCE AquaDam® has been completely installed and filled, now it stands approximately 6ft high. The closed end of the AquaDam® has rolled over the connection collar and the pumps have been moved within 30ft of the collar to fill the next AquaDam.

12.) Workers are attaching the 4ft tall SCE AquaDam® into the connection collar at the closed end of the 6ft tall AquaDam.

13.) The 4ft tall AquaDam® has been fitted into the connection collar. Discharge hoses have been inserted into the fill-tubes. The 4ft tall SCE AquaDam® is now ready to be filled with water.

14.) Four workers are positioned behind the 4ft tall SCE AquaDam, utilizing their hands and legs to prevent the roll from unraveling. Additionally, two workers are holding ropes as a precaution in case the AquaDam® needs to be halted. These ropes can be secured until the workers are prepared to continue their tasks.

15.) The 4ft tall SCE AquaDam® has been installed and connected to the connection collar at the end of the first 6ft tall SCE AquaDam. The flow of the Eagle River has now been forced to the far bank and the work area has been isolated. Workers are now ready to install the another 4ft tall 50ft long SCE AquaDam.

16.) The 4ft tall by 50ft long AquaDam® installation has been completed. It was attached with a connection collar to the closed end of the 4ft tall by 100ft long AquaDam.

17.) Workers then attached a 3ft tall by 100ft long SCE AquaDam® to a connection collar at the closed end of a 4ft tall by 50ft long AquaDam. The 3ft tall AquaDam® closed off the downstream end of the work area.

18.) The water has been redirected to a high-flow channel located on the river bar. The work area has been cordoned off for de-watering purposes. The remaining water within the work area is currently contained and will need to be pumped out to facilitate the de-watering process. Excavation of the work area will commence, reaching a depth of 6 feet below the riverbed to accommodate the installation of intake pipe gallery laterals. A significant portion of the work area will be utilized for the storage of excavated material.

19.) The installation of the AquaDam® cofferdam system has been successfully completed. The Eagle River has been diverted, allowing water to flow through the existing high-water overflow channel. Take note of the foot traffic on top of the AquaDam. A fully deployed AquaDam® serves as an excellent platform for standing and staging equipment.

20.) The Eagle River has been constricted to a narrow 20ft channel, leaving the remaining 80% of the river as an isolated work area. Take note of the pristine water flowing on the right side. A significant amount of boulders had to be extracted in order to create a secure seal for the de-watering process.

21.) This photo showcases the successful completion of the AquaDam® cofferdam system installation. The entire process took approximately 14 hours, excluding the excavation for the intake structure. Kudos to AquaDam® for a job well done!

Various sized AquaDams, River Diversion, Eagle River, Intake Installation