The Imperial Irrigation District (IID)required repairs to one of its head gates, a critical structure that regulates water flow into the settling basin. For this project, the IID selected an AquaDam® as the cofferdam olution. AquaDams® are delivered rolled on a wooden beam, similar to a carpet roll, secured with a protective covering, and equipped with lifting ropes or straps for ease of handling.

The AquaDam® selected for this project is a double closed end (DCE) unit measuring 14ft in height, 29ft in width when fully filled, and 95ft in length. Under optimal conditions, this configuration is capable of controlling up to 110in (approximately 9ft) of combined mud and water depth. The unit has been positioned at the installation site, and the protective wrapping has been removed by the crew in preparation for deployment.

The installation team proceeded to unroll the AquaDam® to an adequate length. This action was necessary to access the fill-tubes and provide sufficient material for securing the unit at the intended launch location.

The installation team proceeded to unroll the AquaDam® to an adequate length. This action was necessary to access the fill-tubes and provide sufficient material for securing the unit at the intended launch location.

Workers are fastening the pull ropes to the crane’s load block. These pull ropes, which come pre-rolled inside the AquaDam®, assist with the unrolling process during installation. While cranes are effective for lifting, they are not suitable for providing controlled directional pulling

As the crane lifts, the attached ropes draw upward, initiating the unrolling of the AquaDam®. Constructed from lightweight, flexible materials, AquaDams® are designed to float when empty, provided the water is sufficiently deep, which facilitates handling and positioning during installation.

The crane operation requires a specific sequence of movements: an upward lift, followed by booming out (extension of the jib), and concluding with a rotation. This coordinated motion is necessary to both facilitate the unrolling of the AquaDam® and achieve the optimal lifting angle for continued deployment.

Sufficient length has now been unrolled to expose the fill tubes. The right side of the core log, around which the AquaDam® was rolled, must be re-positioned to clear the concrete baffle that separates the two head gates.

The AquaDam® has been unrolled past the concrete baffle and is now ready for the crew to begin connecting the pumps for filling the unit.

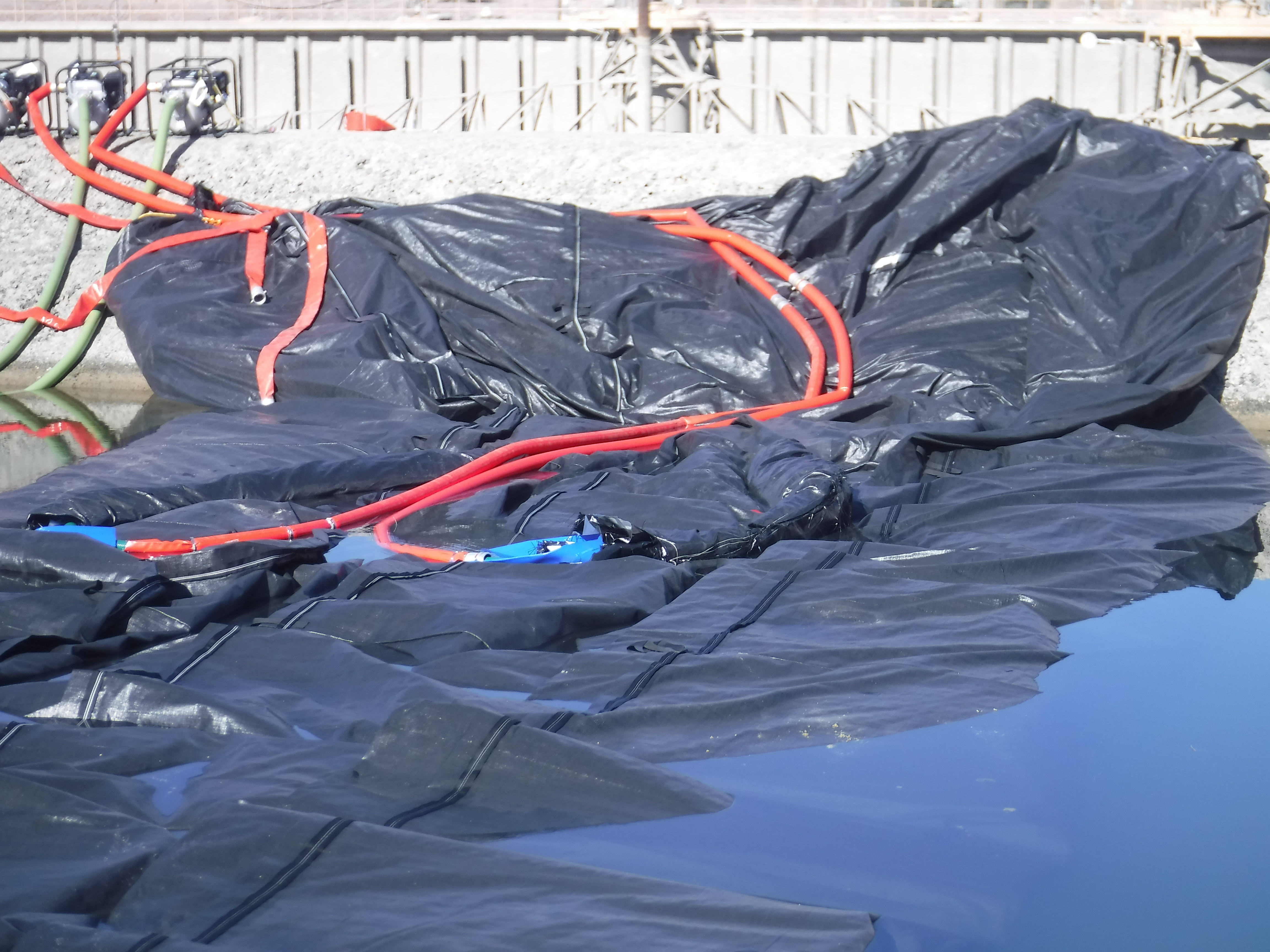

Workers have begun setting up the pumps and laying out the 3in red discharge hoses. Both fill tubes are now visible, each equipped with two 3in blue discharge hoses and one 3in rigid green suction hose. The 3in green suction hose, included with this size AquaDam®, allows air to escape during the rolling process after manufacturing and can also be used to fill the unit with water.

The team has begun filling the 14ft tall by 95ft long DCE AquaDam® using the surrounding water. The red discharge hoses have been connected to the 3in green suction hose supplied with the DCE AquaDam®.

Four gas-powered 3in water pumps were available on site to facilitate filling the AquaDam®. The pumps were strategically positioned on the opposite side of the structure, adjacent to the larger body of water, to optimize intake. At present, two of the four pumps are in operation, as evidenced by the two flattened red discharge hoses visible in this photo.

The 14ft tall DCE AquaDam® is currently in the filling stage. At the launch bank, sections of the dam material have begun to slide down the slope. To maintain proper alignment and stability, the crew must reposition the material by pulling it back up the bank and securing it more effectively.

To maintain stability during filling, the crew secured the AquaDam® material at multiple tie-off points. As water enters the structure, it naturally settles to the lowest areas of the material, exerting downward force that can draw the dam out of alignment. Additionally, any water flow within the basin will apply lateral pressure, attempting to push the AquaDam® in the direction of the current. Proper anchoring is therefore essential to ensure the unit remains securely positioned throughout the filling process.

The 14ft tall DCE AquaDam® is shown filling from another angle. An AquaDam® will only achieve its full height in the deepest sections of the waterway where it is deployed. During the filling process, ropes are essential to maintain the dam’s position and prevent shifting. Once the AquaDam® has developed sufficient head above the surrounding water, select positioning ropes may be removed, as the structure will then stabilize under its own weight and buoyancy.

Workers secured ropes through loops sewn into the AquaDam® and attached them to thin metal pipes to serve as an anchoring system. For a dam of this size, it is strongly recommended to provide additional anchoring support, ideally two to three times more than what is shown here, to ensure stability during filling.

The 95ft long DCE AquaDam® continues to fill and now has approximately 6in of head above the surrounding water. As the dam fills, water is climbing up the end bank and causing material to unwind from the roll.

The 14ft tall DCE AquaDam® has reached approximately 1ft of head above the surrounding water. The roll end of the unit is now positioned securely on the terminal bank, marking a key stage in the filling process.

Workers have secured a gut rope around the AquaDam® to tie off the remaining rolled-up length and core log. The gut rope includes loops for multiple tie-off points, ensuring the unit remains stable during installation.

The ending bank for this AquaDam® is situated along one of the outlet weir walls of a settling basin located just below Imperial Dam. With three settling basins at this site, the loss of one presents operational challenges. To mitigate this, workers installed a 1.5ft tall AquaDam® along the crest of the weir wall, directing water downstream of the ending bank of the 14ft tall DCE AquaDam®. At present, the smaller AquaDam® is only about one-quarter full.

The 14ft tall by 95ft long DCE AquaDam® is now fully filled, properly positioned, and securely tied off. The installation team executed the deployment effectively, ensuring the dam is stable and operational.

It may be difficult to discern, but the AquaDam® is positioned within a deep hole just before ascending the ending bank. This is evident from the noticeably slimmer profile of the unit immediately to the left of the rope tied off near the cameraman’s position.

The following morning provides a clear view of both AquaDams® in place.

The 1.5ft tall AquaDam® is now fully filled and ready for operation.

The 1.5ft tall AquaDam® is now fully filled and ready for operation.

The 1.5ft tall secondary AquaDam® is currently performing its critical function by effectively preventing water infiltration along the ending bank of the main 14ft DCE AquaDam®. This successful diversion is essential for maintaining the dry work area adjacent to the primary unit.

Excellent work by everyone involved in this project!

14ft Tall, 28ft Wide When Full, 95ft Long Double Closed End (DCE) AquaDam®, Colorado River, Imperial Irrigation District, Imperial Dam, All-American Canal System, Head Gate Repair, Line Configuration